Having a temperature sensor + peltier element would be a great add to this system! The way we developed things in the FlyPi was def. sub-optimal as it was all part of the first more "serious" interaction with electronics and as you mention there are a couple of things that could be done better:

-

An analog temp sensor was used there, which is not a terrible idea, but that is quite prone to variance, depending on how the system is set, quality of solder, etc. Also it "blocks" an analog input port. I think this time around we would be better off using a sensor that outputs digital data? Something like the ds18b20 looks nice as it provides 0.5C accuracy over -10 to +85C range, and is transmits data over 1-wire protocol, so several can be used in the same data line. (But if you have other suggestions, let's chat about it!)

-

As you mention we used the L298N, but as far as I remember, we mostly used it to flip current direction but always in full cycle, I don't think we used PWM with it. In any case, we also did a lot of cycling to keep the temperature at the desired state, which from the material you sent, is also not a good way to go. At some point it would be good to implement some code for PID control (maybe there are python libraries we can import to micropython)

-

all this said, if you have the time to figure out a better way to implement the electronics for this, that would be much appreciated! :)

I plan to modify it a bit. But if it was changed at some point, I hope to see how.

I plan to modify it a bit. But if it was changed at some point, I hope to see how.

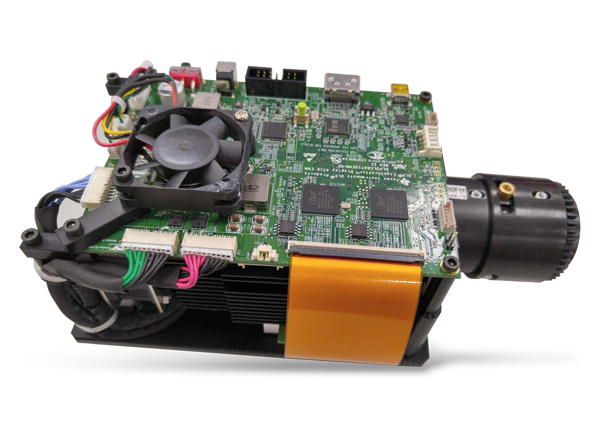

Fig. 1 - Circuitry

Fig. 1 - Circuitry

Fig. 1 - PCB design

Fig. 1 - PCB design Fig. 1 - Q1 and Q3

Maybe some solder got on their tracks. What about the other pair of MOSFETs?

Fig. 1 - Q1 and Q3

Maybe some solder got on their tracks. What about the other pair of MOSFETs?

Fig.1 - TC4420 structure

Fig.1 - TC4420 structure

The previous installation of Peltier element has an L298N as a driver. The questions here are whether it is effective and are there any changes that need to be implemented? Also, there is a thermistor that is used to monitor temperature, any changes here?

Some background information. From what I have found out, the L298N can be controlled with PWM signals and that is exactly how it is done in FlyPi. However, there is a lost of efficiency when using pure PWM (a change between HIGH and LOW with different time intervals) due to the fact that this way Peltier is driven by current that changes from 0 to some max value. It is a problem because efficient cooling and heating of Peltier is achieved with current that is not 0 nor max value. Therefore, DC should be used (note 1 and note 2). It means that we need to control current flow either by filtering PWM signal or by a current regulator.