I attach the code block to read the measurements here:

with utilities.DeviceConnection.createTcpConnection(args) as router:

with utilities.DeviceConnection.createUdpConnection(args) as router_real_time:

# Create required services

base = BaseClient(router)

base_cyclic = BaseCyclicClient(router_real_time)

input("INFO: press enter to start collecting data")

for _ in range(tot_num_steps):

iter_start_time = time.time()

base_feedback = BaseCyclic_pb2.Feedback()

base_feedback = SendCallWithRetry(base_cyclic.RefreshFeedback, 3)

ee_x = base_feedback.base.tool_pose_x # (meters)

ee_y = base_feedback.base.tool_pose_y # (meters)

ee_z = base_feedback.base.tool_pose_z # (meters)

ee_theta_x = base_feedback.base.tool_pose_theta_x # (degrees)

ee_theta_y = base_feedback.base.tool_pose_theta_y # (degrees)

ee_theta_z = base_feedback.base.tool_pose_theta_z # (degrees)

ee_pose_vec = np.array([[ee_x, ee_y, ee_z, ee_theta_x, ee_theta_y, ee_theta_z]])

ee_pose_ary = np.append(ee_pose_ary, ee_pose_vec, axis=0)

f_x = base_feedback.base.tool_external_wrench_force_x

f_y = base_feedback.base.tool_external_wrench_force_y

f_z = base_feedback.base.tool_external_wrench_force_z

tau_x = base_feedback.base.tool_external_wrench_torque_x

tau_y = base_feedback.base.tool_external_wrench_torque_y

tau_z = base_feedback.base.tool_external_wrench_torque_z

f_vec = np.array([[f_x, f_y, f_z, tau_x, tau_y, tau_z]])

wrench_ary = np.append(wrench_ary, f_vec, axis=0)

Summary

Improve end-effector force/torque measurement accuracy.

Use case

Detect end-effector collision with other objects or control contact force. Currently the end-effector APIs

base_feedback.base.tool_external_wrench_force_x/y/zandbase_feedback.base.tool_external_wrench_torque_x/y/zare not sufficiently accurate.Alternative

Maybe there is a way to calibrate the wrench measurement?

Possible issues

Should not have negative impacts on other features.

Additional context

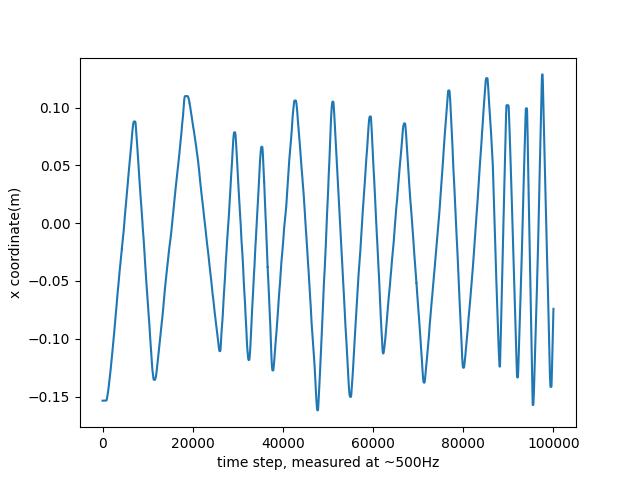

Here is an experiment I have on the current end-effector wrench measurements API, where the robot arm periodically moves forward and backward in the x-axis. The first figure show the relation between x-axis coordinate over time:

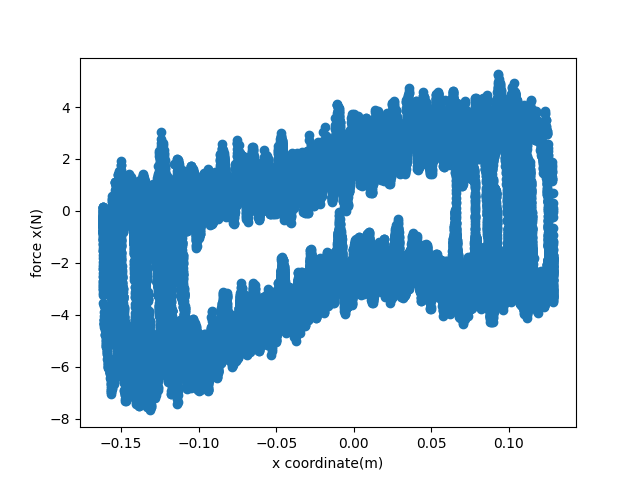

The second figure shows the force in the x direction measured at each x coordinate, in a scatter plot:

We may see depending on different moving directions, the force measurements are quite different. For more information, there is the robotiq85 gripper mounted on the end-effector and there is no object grasped or hanging on the gripper. So I expected zero force and torque measurements of the end-effector wrench.