I think you're onto something. This is the constructor for TMC26XStepper…

TMC26XStepper(int number_of_steps, int cs_pin, int dir_pin, int step_pin, unsigned int current, unsigned int resistor=150);Closed chriscg9 closed 5 years ago

I think you're onto something. This is the constructor for TMC26XStepper…

TMC26XStepper(int number_of_steps, int cs_pin, int dir_pin, int step_pin, unsigned int current, unsigned int resistor=150);Any thoughts on the changes?

The initializer change in stepper_indirection.h fixes a bug, so that's a good start!

But the change to Marlin.h is not needed, because we have these in Configuration.h:

// For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1

// :{ 0:'Low', 1:'High' }

#define X_ENABLE_ON 0

#define Y_ENABLE_ON 0

#define Z_ENABLE_ON 0

#define E_ENABLE_ON 0 // For all extruders…and they can just be set to 1 to invert the logic.

If the entire TMC26x line consistently inverts these pins, then this is something we should alert users about in the sanity-check file. Otherwise, we'll just have to document this consideration in a comment above the HAVE_TMC26X option in Configuration_adv.h.

I'll patch the first issue in the bugfix branches now, and then check the datasheets to see what we need to do about the second issue.

According to the datasheet the DRV_ENN pin is Active Low. If connecting to that pin, then the default of X_ENABLE_ON 0 should be correct, with no need to modify the code.

Awesome. Would it be better i just fix my code or download the bugfix branch?

Thanks for your help. I did not see the invert enable when skimming the config file thanks.

Do you have any recommendations as to what to set the microstep amount? Will i be limited in my top speed by setting it to the full 256? vs setting it to say 64? Or will the top end not be noticeable? My machine does have a very heavy XY gantry so i cant go to any crazy speeds.

Not my picture but this is what my gantry looks like

I recommend the latest bug fix code. It’s more mature than 1.1.8.

Don’t use direct micro-stepping over 32x with an AVR-based board, and don’t use more than 16x micro-stepping on the Z axis and extruder. Your speeds will be limited by anything over these, and can even lead to rebooting the board.

If you don’t see the invert enable options by skimming, then use the Find command in your favorite multi-file text editor instead.

Okay thanks for the advice on the steps.

What board would be able to handle the full 256 steps and still ramps compatible? Re-arm or due? Any one better than the other?

Due runs 4-5 times faster than AVR. Re-Arm runs 6-7 times faster. Either one should be more than capable of keeping up with 256 real micro-steps at typical printing speeds.

Note that Due is not RAMPS compatible. It requires a RAMPS4DUE with 3.3v support.

@chriscg9 is this one "solved" ?

Yes it is solved.

This issue has been automatically locked since there has not been any recent activity after it was closed. Please open a new issue for related bugs.

TMC262BOB40 does not to function. Link to product page https://www.digikey.com/product-detail/en/trinamic-motion-control-gmbh/TMC262-BOB40/1460-1243-ND/8037670 When configured in the firmware the drivers do not work

I decided to do some digging and found somethings that once changed allowed this driver to function. stepper_indirection.cpp Was (Enable is done via spi not pins so why is enable pin set here?)

Fixed (changed the order and switched enable with CS)

With this changed i noticed that once the board booted up the motor would enable and hold rotor position and when told to move it would stop holding rotor position. So it would seem the logic is reversed for enable in SPI or just this BOB is different than the normal 26x boards.

I found what i was looking for and changed them see comment for what it was

So i am unsure if the changes i have made will have any ill consequences down the road. But for the moment i am able to run the motors and power some very big steppers considering i get a full 2.8A at 40V

Any thoughts on the changes?

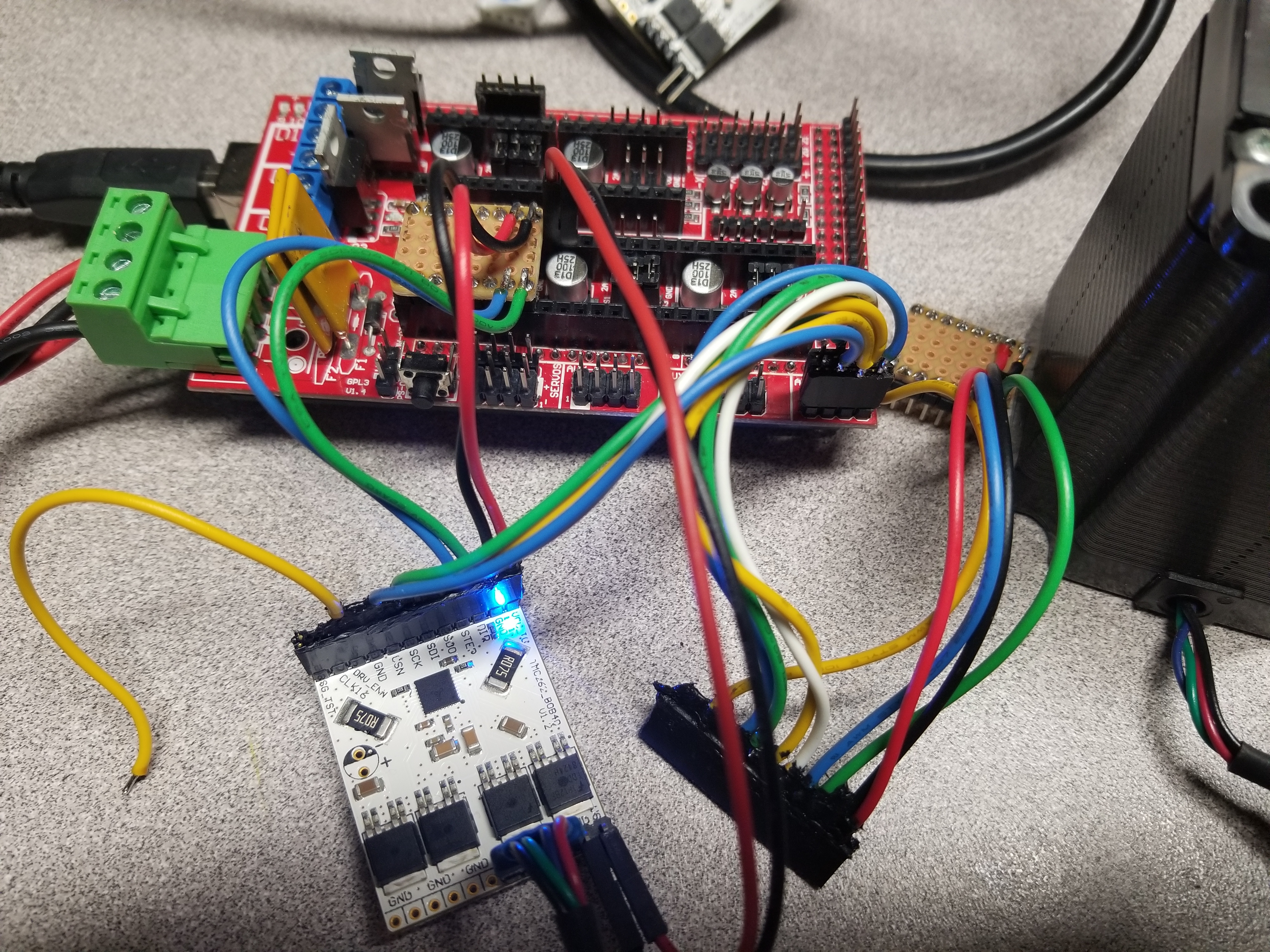

Picture of rough setup for bench testing before being put into a Stratasys FDM