In looking over things, I think I can see some of what can happen with ubl and a tool change. Now that a commit was added to make the planner aware of corrected position, it may no longer occur however for dual x carriage we can try mimicking the home command for disabling and restoring bed leveling.

#if HAS_LEVELING

#if ENABLED(RESTORE_LEVELING_AFTER_G28)

const bool leveling_was_active = planner.leveling_active;

#endif

set_bed_leveling_enabled(false);

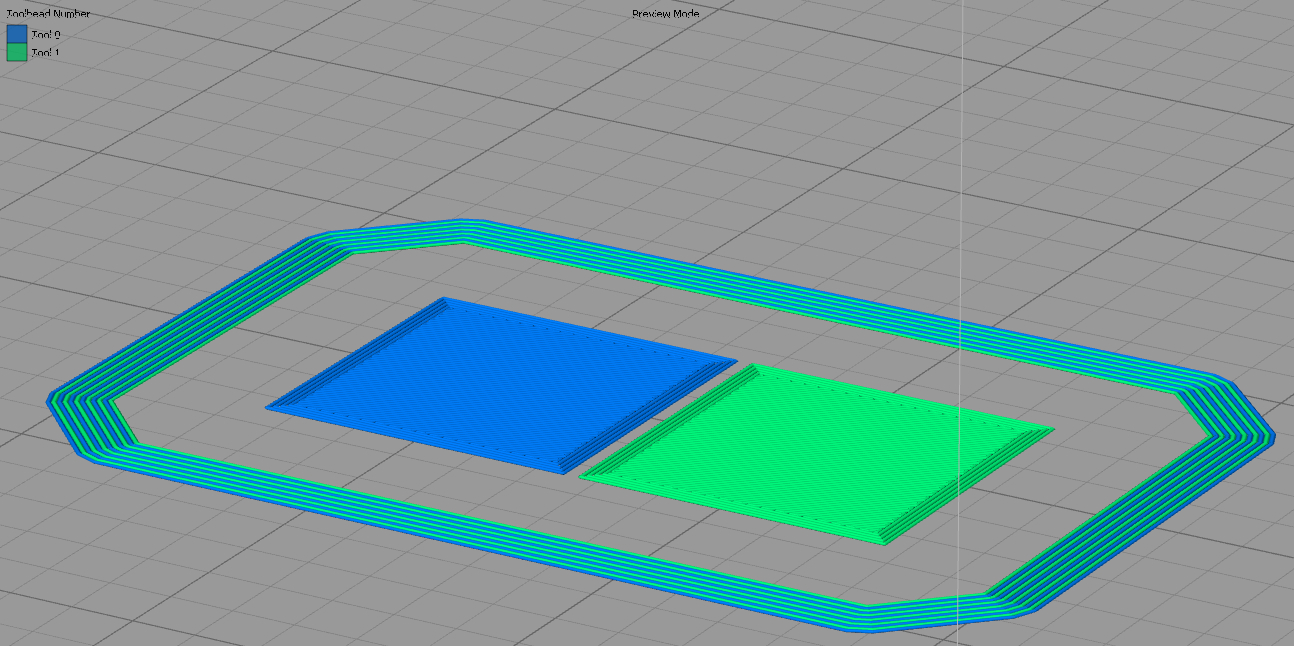

#endifIf the bed has an even tilt, which kills duplicate mode btw so for an idex machine shouldnt be left there, i can see ubl adjusting following the park and recall commands causing #11330 however its likely not noticed often as duplicate mode requires fairly accurate bed leveling, using ubl as a visual aid for it. Now that the planner is aware of the position, can you see if this still occurs? If so, ill send you a patched branch with UBL disabled and restored around tool change. Im hesitant to slant the bed on my only idex machine enough to cause this, since ive still got delivery times to make.

https://github.com/MarlinFirmware/Marlin/issues/11330 https://github.com/MarlinFirmware/Marlin/issues/10749 Posting this as I feel it was missed by @Roxy-3D & @thinkyhead Thanks