@VincentWiz Our bed tramming algorithms try to keep the distance bed-probe constant. This works pretty well as long the distance between nozzle and probe is constant. X-rotation prevents that https://github.com/MarlinFirmware/Marlin/issues/9529#issuecomment-365298112 and follwups made this a bit clarer to some.

@filipgoc Right. Almost everything can be fixed in software. The question here is if it can be done in the time we have and where can we get the needed data. This is a nonlinear problem. Until someone finds a trick we'd have to calc a sin() and or cos(). Because a similar problem exists for Y the amount of calculations will grow fast. (An idea could be to apply the correction not to every point we go, but only to tune the mesh (if we have one)). An alternative for hand tuning the mesh. While thinking about it - hand tuning the UBL mesh is the procedure to get the required data.)

@thinkyhead

Somewhere else you talked about a test to compare the probes result with a nozzle-paper-test in the mid of the bed to find the Z_PROBE_OFFSET_FROM_EXTRUDER. For debugging purpose a way to make this test at X Y or at the current position would be nice.

Bug Report

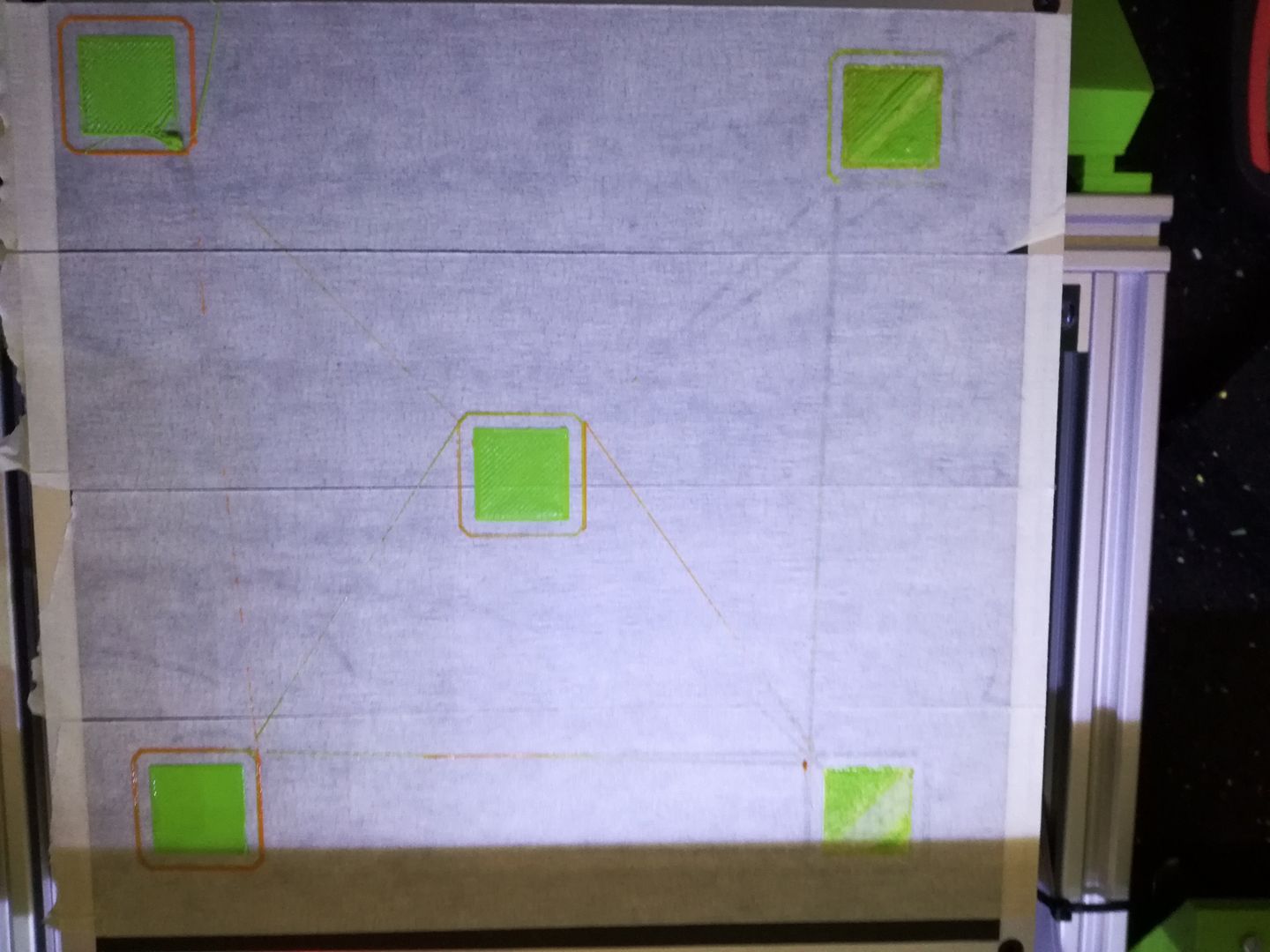

Description: On Marlin 1.1.8, using capacitive sensor and Bilinear autolevel method, the bed isn't flat everywhere. A discussion has been open in a group on Facebook, and many people are having this issue. I tried to clear EEPROM then re-upload Marlin, no effects. I also tried to go on Marlin1.1.6, same. Other people has the BLTouch, so the issue isn't comming from the sensor. Some people are also on Marlin 1.1.6. I wanted to use the UBL for checking, but i has a compilation error (Text overflowed). I'll post my configuration.h and conf_adv.h this evening.

Expected behaviour: Autolevel should compense the Z offset everywhere on the bed

Actual behaviour: Autolevel doesn't compense the Z offset everywhere (check the picture attached - Don't take care about the bad stuff, because i had no scotch on all bed xD, just take care about the lines, and Z-offset)

With capacitive sensor

With BLTouch