Greetings!

To calculate the drag force of 40kN, you can start by using simple geometry such as a sphere or a vector cylinder in 2D or 3D. You will need the drag coefficient, air density, and the geometry to calculate the air forces. Once you have calculated the air forces, you can convert them to LBM units.

If you need an example, let me know and I can show you some. Also, if you have an STL file, you can use it to help with the calculation of dry forces.

Regarding your air wing, you mentioned that it is four instead of two which is an interesting point. It might take some time to calculate, but you can give it a try.

Let me know if there's anything else I can help with!

I'm trying to do a rough calculation of the maximum airspeed attainable by a particular aircraft. I've completed some force simulations in other sims before, but not one where I have a set amount of available thrust (40 kN) and plan to increase the lbm_u flow speed until the total drag force in the y-axis equals this amount.

The problem is I can't really seem to get the conversion to/from real life to sim units correct in the code (or in my head) as far as I can tell + Primarily I'm not sure of how to determine the real life airspeed based on the _lbmu flow speed.

(The results are also very unstable and can't get the simulation to converge on an accurate value, but one problem at a time 🤔)

I've read right through these other issue threads (https://github.com/ProjectPhysX/FluidX3D/issues/36, https://github.com/ProjectPhysX/FluidX3D/issues/32) relating to force readouts but I think I'm still missing something here. My code and force results are below:

My defines header here:

```cpp #pragma once //#define D2Q9 // choose D2Q9 velocity set for 2D; allocates 53 (FP32) or 35 (FP16) Bytes/node //#define D3Q15 // choose D3Q15 velocity set for 3D; allocates 77 (FP32) or 47 (FP16) Bytes/node //#define D3Q19 // choose D3Q19 velocity set for 3D; allocates 93 (FP32) or 55 (FP16) Bytes/node; (default) #define D3Q27 // choose D3Q27 velocity set for 3D; allocates 125 (FP32) or 71 (FP16) Bytes/node #define SRT // choose single-relaxation-time LBM collision operator; (default) //#define TRT // choose two-relaxation-time LBM collision operator //#define FP16S // compress LBM DDFs to range-shifted IEEE-754 FP16; number conversion is done in hardware; all arithmetic is still done in FP32 //#define FP16C // compress LBM DDFs to more accurate custom FP16C format; number conversion is emulated in software; all arithmetic is still done in FP32 //#define BENCHMARK // disable all extensions and setups and run benchmark setup instead //#define VOLUME_FORCE // enables global force per volume in one direction, specified in the LBM class constructor; the force can be changed on-the-fly between time steps at no performance cost #define FORCE_FIELD // enables computing the forces on solid boundaries with lbm.calculate_force_on_boundaries(); and enables setting the force for each lattice point independently (enable VOLUME_FORCE too); allocates an extra 12 Bytes/node //#define MOVING_BOUNDARIES // enables moving solids: set solid nodes to TYPE_S and set their velocity u unequal to zero #define EQUILIBRIUM_BOUNDARIES // enables fixing the velocity/density by marking nodes with TYPE_E; can be used for inflow/outflow; does not reflect shock waves //#define SURFACE // enables free surface LBM: mark fluid nodes with TYPE_F; at initialization the TYPE_I interface and TYPE_G gas domains will automatically be completed; allocates an extra 12 Bytes/node //#define TEMPERATURE // enables temperature extension; set fixed-temperature nodes with TYPE_T (similar to EQUILIBRIUM_BOUNDARIES); allocates an extra 32 (FP32) or 18 (FP16) Bytes/node #define SUBGRID // enables Smagorinsky-Lilly subgrid turbulence model to keep simulations with very large Reynolds number stable #define INTERACTIVE_GRAPHICS // enable interactive graphics; start/pause the simulation by pressing P; either Windows or Linux X11 desktop must be available; on Linux: change to "compile on Linux with X11" command in make.sh //#define INTERACTIVE_GRAPHICS_ASCII // enable interactive graphics in ASCII mode the console; start/pause the simulation by pressing P //#define GRAPHICS // run FluidX3D in the console, but still enable graphics functionality for writing rendered frames to the hard drive #define GRAPHICS_FRAME_WIDTH 3840 // set frame width if only GRAPHICS is enabled #define GRAPHICS_FRAME_HEIGHT 2160 // set frame height if only GRAPHICS is enabled #define GRAPHICS_BACKGROUND_COLOR 0x000000 // set background color; black background (default) = 0x000000, white background = 0xFFFFFF #define GRAPHICS_U_MAX 0.18f // maximum velocity for velocity coloring in units of LBM lattice speed of sound (c=1/sqrt(3)) (default: 0.15f) #define GRAPHICS_Q_CRITERION 0.0001f // Q-criterion value for Q-criterion isosurface visualization (default: 0.0001f) #define GRAPHICS_BOUNDARY_FORCE_SCALE 100.0f // scaling factor for visualization of forces on solid boundaries if VOLUME_FORCE is enabled and lbm.calculate_force_on_boundaries(); is called (default: 100.0f) #define GRAPHICS_STREAMLINE_SPARSE 47 // set how many streamlines there are every x lattice points #define GRAPHICS_STREAMLINE_LENGTH 256 // set maximum length of streamlines // ############################################################################################################# #define TYPE_S 0b00000001 // (stationary or moving) solid boundary #define TYPE_E 0b00000010 // equilibrium boundary (inflow/outflow) #define TYPE_T 0b00000100 // temperature boundary #define TYPE_F 0b00001000 // fluid #define TYPE_I 0b00010000 // interface #define TYPE_G 0b00100000 // gas #define TYPE_X 0b01000000 // reserved type X #define TYPE_Y 0b10000000 // reserved type Y #if defined(FP16S) || defined(FP16C) #define fpxx ushort #else // FP32 #define fpxx float #endif // FP32 #ifdef BENCHMARK #undef UPDATE_FIELDS #undef VOLUME_FORCE #undef FORCE_FIELD #undef MOVING_BOUNDARIES #undef EQUILIBRIUM_BOUNDARIES #undef SURFACE #undef TEMPERATURE #undef SUBGRID #undef INTERACTIVE_GRAPHICS #undef INTERACTIVE_GRAPHICS_ASCII #undef GRAPHICS #endif // BENCHMARK #ifdef SURFACE // (rho, u) need to be updated exactly every LBM step #define UPDATE_FIELDS // update (rho, u, T) in every LBM step #endif // SURFACE #ifdef TEMPERATURE #define VOLUME_FORCE #endif // TEMPERATURE #if defined(INTERACTIVE_GRAPHICS) || defined(INTERACTIVE_GRAPHICS_ASCII) #define GRAPHICS #endif // INTERACTIVE_GRAPHICS || INTERACTIVE_GRAPHICS_ASCII ```Here's a snippet of the force results output (does anyone know how to get the output to not be scientific notation? Google Sheets doesn't handle these values and I have to resort to MS Excel):

Force Calculation Results

### Taken each 100 steps ``` 5.45981456E4 7.24956846E4 7.05784989E4 4.87261344E4 5.33241606E4 4.76977920E4 4.39427472E4 4.65264656E4 4.49056340E4 4.15205240E4 4.89547016E4 4.37330200E4 3.41821480E4 5.59037636E4 3.54986192E4 3.03640080E4 6.60130216E4 1.98685264E4 4.37987564E4 5.84950160E4 1.40907776E4 5.30362702E4 4.93470624E4 1.66901088E4 6.21138572E4 3.50296092E4 2.53584744E4 6.05184031E4 2.65506504E4 3.66595888E4 5.78224232E4 2.07870364E4 4.56666420E4 4.79558512E4 2.18530130E4 5.24934960E4 4.20690488E4 2.38719248E4 5.73561760E4 3.04396701E4 3.29020452E4 5.45614432E4 2.86208776E4 3.78154800E4 5.19157028E4 2.27532816E4 4.62905692E4 4.43532228E4 2.78953000E4 4.90866040E4 3.82027696E4 2.95206312E4 5.04203034E4 3.29360580E4 3.73151400E4 4.77963496E4 3.10918498E4 3.99938512E4 4.41328812E4 2.99023864E4 4.72581864E4 3.70907136E4 3.52803944E4 4.51192808E4 3.29675292E4 3.91297720E4 4.56213856E4 3.03644109E4 4.48174240E4 3.93006824E4 3.07123041E4 4.83290144E4 3.47505568E4 3.55810620E4 4.79376888E4 2.96577928E4 3.90675064E4 4.69986776E4 2.75215248E4 4.63786412E4 4.14923382E4 2.75947616E4 4.86272048E4 3.66286016E4 3.10061097E4 5.13841009E4 3.11370969E4 3.47928692E4 5.00028658E4 2.79550312E4 3.98808744E4 4.84784648E4 2.45359184E4 4.63440372E4 4.16207886E4 2.70788336E4 4.90002344E4 3.83687952E4 2.75404432E4 5.26642036E4 3.07034731E4 3.39467932E4 5.09975672E4 2.84062696E4 3.78370336E4 5.01098347E4 2.38102340E4 4.47991560E4 4.50371884E4 2.43556548E4 4.90558720E4 3.96822504E4 2.49006056E4 5.38041876E4 3.20686198E4 3.12109590E4 5.30605126E4 2.81475904E4 3.52483344E4 5.24868106E4 2.32955694E4 4.32908916E4 4.73114536E4 2.31392718E4 4.78467272E4 4.26806164E4 2.36173772E4 5.27146720E4 3.64221096E4 2.72658848E4 5.37688492E4 3.21892882E4 3.15374017E4 5.30127192E4 2.87015728E4 3.51730704E4 5.13758898E4 2.62463404E4 4.04599190E4 4.75241136E4 2.80091504E4 4.12005997E4 4.52993488E4 2.95608160E4 4.34895752E4 4.26450872E4 3.17720150E4 4.10161400E4 4.15983200E4 3.45705508E4 4.11882591E4 4.11889410E4 3.62099792E4 3.64361740E4 4.39449404E4 3.55373500E4 3.74828080E4 4.55044604E4 3.47750972E4 3.48780344E4 4.73938992E4 3.23299218E4 3.82154488E4 4.80530736E4 3.00424647E4 3.91072776E4 4.62211560E4 2.82382848E4 4.31937932E4 4.56638528E4 2.68889168E4 4.58463956E4 4.08407545E4 2.79705000E4 4.83229064E4 3.97819688E4 2.86021256E4 4.94393400E4 3.49910664E4 3.12321615E4 5.04131508E4 3.44256544E4 3.30876518E4 5.02775574E4 2.88833376E4 3.78664400E4 4.77260304E4 3.04172182E4 4.01574278E4 4.58602380E4 2.68378544E4 4.47494124E4 4.18165016E4 3.05465555E4 4.53165436E4 3.94830728E4 2.89034680E4 4.83971688E4 3.50941636E4 3.48705148E4 4.67443224E4 3.39380216E4 3.38679432E4 4.85436392E4 3.05737758E4 4.04101801E4 4.52647828E4 3.02574444E4 4.03174400E4 4.44756936E4 2.88578224E4 4.54932880E4 4.09248829E4 2.99064352E4 4.50767516E4 3.92672752E4 3.06318474E4 4.82059480E4 3.57805896E4 3.25918674E4 4.66934728E4 3.37587928E4 3.48344444E4 4.87301160E4 3.17187286E4 3.70109248E4 4.61975004E4 2.93210528E4 4.05846787E4 4.57513000E4 2.92939016E4 4.27224446E4 4.21224594E4 2.82099104E4 4.62798644E4 3.98973344E4 3.09912205E4 4.61989500E4 3.70167640E4 3.05215764E4 4.95039272E4 3.33795764E4 3.57161308E4 4.69126512E4 3.14432621E4 3.61775900E4 4.83867120E4 2.86830904E4 4.32326270E4 4.34546520E4 2.88929984E4 4.28917074E4 4.26834106E4 2.88632296E4 4.81515312E4 3.75875688E4 3.07526446E4 4.73358968E4 3.54067968E4 3.24639488E4 5.02047062E4 3.08033443E4 3.67542480E4 4.71359352E4 3.03295064E4 ```So the forces seem in the ballpark of 40 kN, but what would I say the real-life airspeed of the simulation is here?

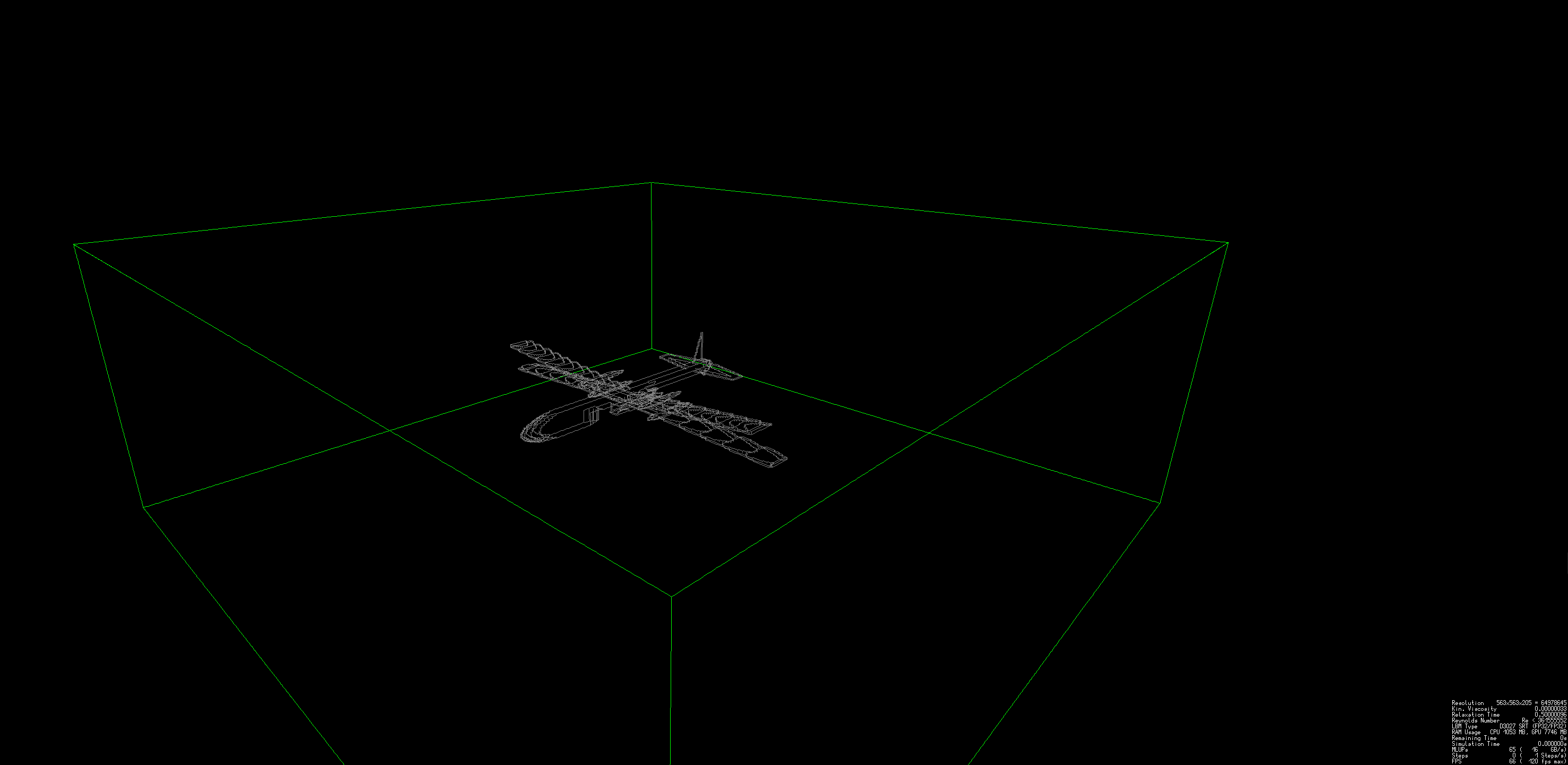

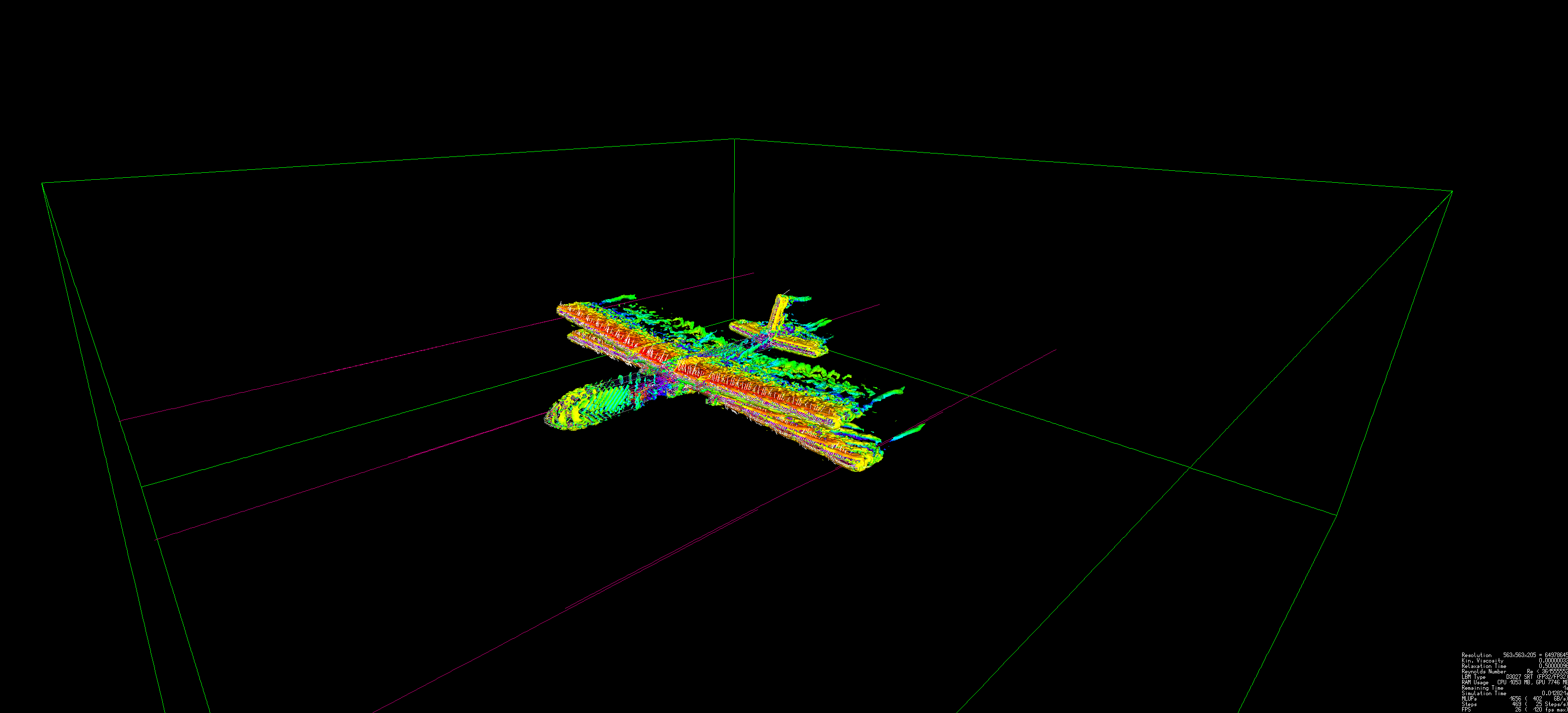

Screenshots:

Plenty of volume around the aircraft:  Early in the sim (force lines start flailing around further into the simulation): The results are all over the place and I'm completely stuck now. Can anyone see where I'm going wrong and/or how I can get the results I'm looking for? 😟