WOW, thanks for the feedback. Let's see if I can answer your points, let me know if I miss anything.

1- I'm not using the RTC for anything and it might not even make sense to have this broken out but I thought someone could find a use for it. All the settings are indeed stored to flash so a battery is not required, this would only be used for time keeping and for this you would need to solder a 32.768kHz crystal and the respective load capacitors (Y1, C9, C10). To answer your question, yes you can cut the traces and use for something else but all unused (and some used, USB) pins are already broken out to the EXP header.

2- I didn't have this issue while soldering, the pad actually has thermal reliefs, I might have to check this as you make a good point with with the cheaper soldering irons. I actually widened the pads for the JST's and the THT resistors for the RP2040 version as they turned out quite small on this board. To be honest I don't know if I will continue to offer the kits, it turns out it takes a lot more time to put all the kits together than to actually solder everything.

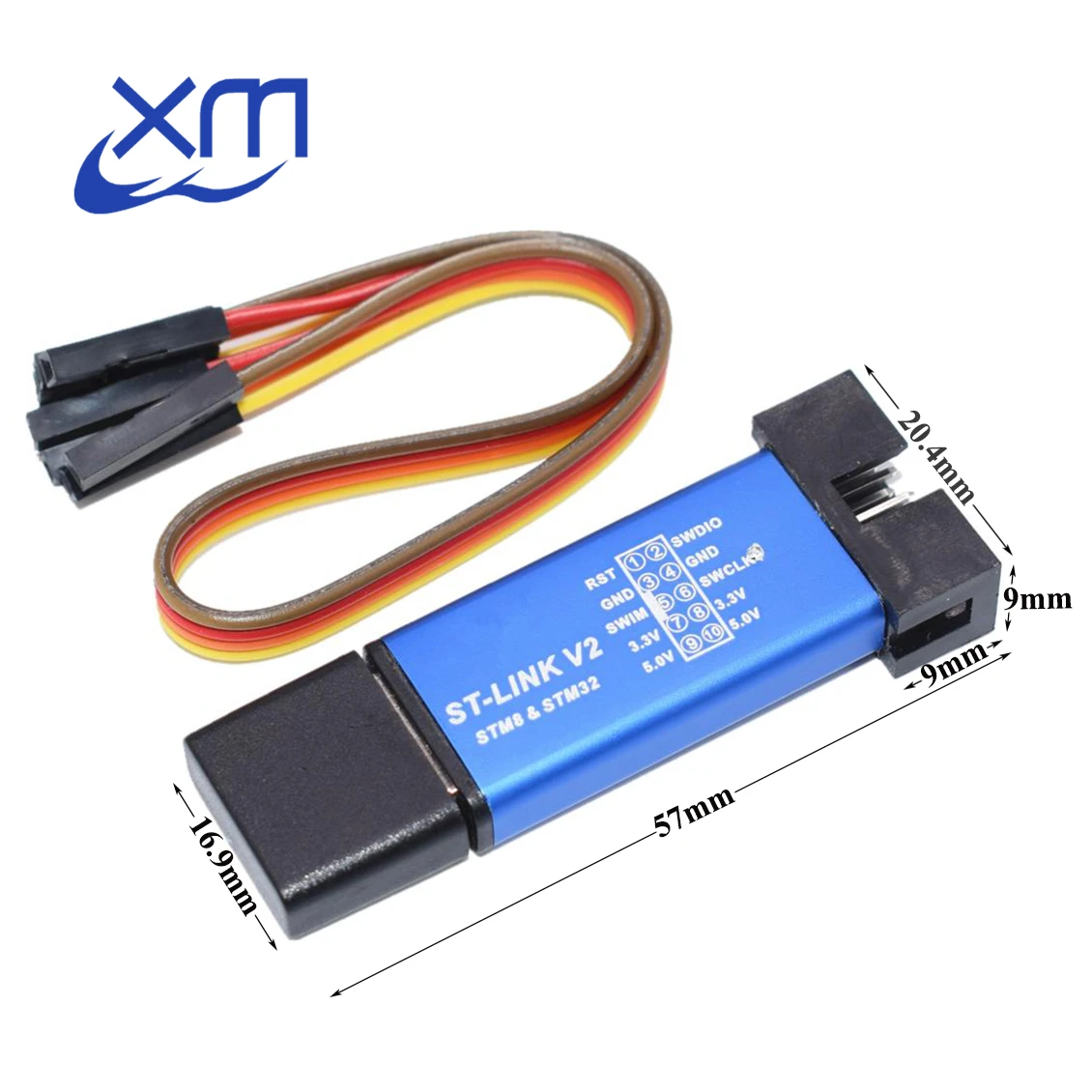

3- I actually never program this with the SWDIO and SWCLK pins, I initially flash the bootloader with the TX and RX pins and then I just use USB to upload the firmware. I will take this into consideration in the next revision.

5- Yes, I forgot to edit the footprint's silkscreen, that + should not be there, as this is a passive buzzer the polarity should not matter, it only changes the direction the piezo element bends to, I didn't notice any volume difference on the boards I soldered. I already fixed this for the RP2040 version.

6/7- These are BOOT 0 and BOOT 1 they are set with a solder jumper but if you want to tinker with the board you can remove the solder and solder pins and use those tiny header jumpers 😉

For my daily use 3 presets are enough, I use one for heatshrink one for normal rework and one for higher temps, for anything else I just use the pots. You have some nice ideas I'm eager to see some hacks on my board hehe

Hi there, I am very pleased with this upgrade kit. And grateful for it. My prayers answered. However i did notice a few things inspecting the PCB. And just wanted to let you know. In case you decide to make revisions or updates for future runs.

Most of these are minor small points. Nothing really too important. So please don't take it as any criticism - you have done an excellent work. And with all the most important aspect really well done.

You can see here is a numbered list, for each point.

[ 0v, SWD_CLK, SWDIO, 3v3, NRST ]. Or however you want to include them.[ 3v3, BOOT0, GND ]. To pull it high or low (while flashing). Otherwise it floats internallySo that is all I can see here for suggestions to improve the PCB.

Programming / Debugging

3v3rail from the programmer. It draws only43mA, which is great. Enough for the programmer to power the device during flashing etc. Without browning out. OK then!3v3pin. Only theGNDpin, to maintain a ground reference.Actually you did a really great job for the firmware. I do not plan to change very much. Except maybe if I require more than 3 presets. Then perhaps the buttons can be changed to scroll through numbered list of presets. Up, down, and select. Instead of directly switching to the preset.

However I will not add this until I really know that I need to keep more than 3 presets. So perhaps it won't be needed, then I will not add this.

And of course, as you also mention in your video: it is great to use the GPIO header, for connecting another slave device to control. For example fume extractor on/off. Or for attaching another input device, such as a foot switch pedal(s). So that hands are free. Thank you so much my friend!