You have to switch off calibration (-n)

We are working on the power curve. I have a fork, with adapted power curves for i-Flow and i-Magic https://github.com/cyclingflow/FortiusANT/releases You might want to try that. Please, use the included .bat files, they will specify the correct command line parameters.

Discussion is in https://github.com/WouterJD/FortiusANT/issues/143

BTW. I have recently increased the tire resistance to prevent slipping. (mine now has a calibration factor of 5 on the manual control unit) so, the curves are calibrated a bit above the normal low settings of your flow. Of course it depends on your tire pressure and knob setting.

So for example if you set the target to 1559 (one of the discrete values) you still get 1039. You would have to program something like 2145 to get 1559. This was already noted by @cyclingflow, but unless I am missing something, the current code in the iMagic branch does not take this into account.

So for example if you set the target to 1559 (one of the discrete values) you still get 1039. You would have to program something like 2145 to get 1559. This was already noted by @cyclingflow, but unless I am missing something, the current code in the iMagic branch does not take this into account.

hello Wouter , is it possible to have a correct powercurve for the Tacx Flow T2250 , the current powercurve is far off and i could not find a good way to adjust it to my Garmin vector 2 powermeter reading

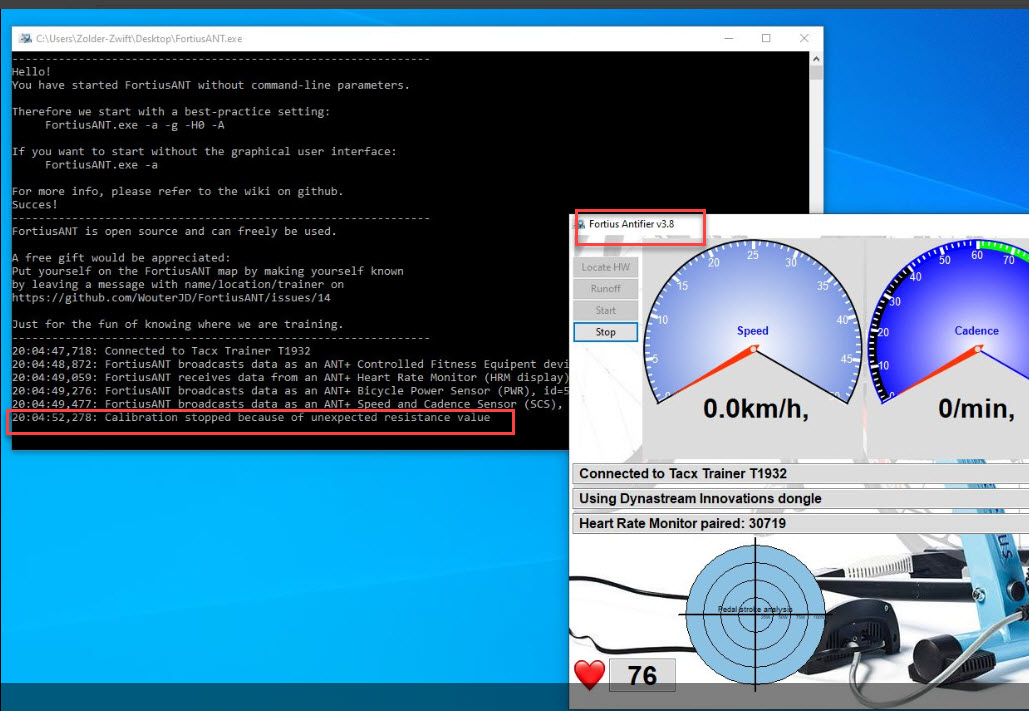

What i noticed , see screenshot is that the calibration of my Flow motor give an error during initialization "calibration stopped because of unexpected resistance value

by FortiusAnt

by FortiusAnt

grt jurgen