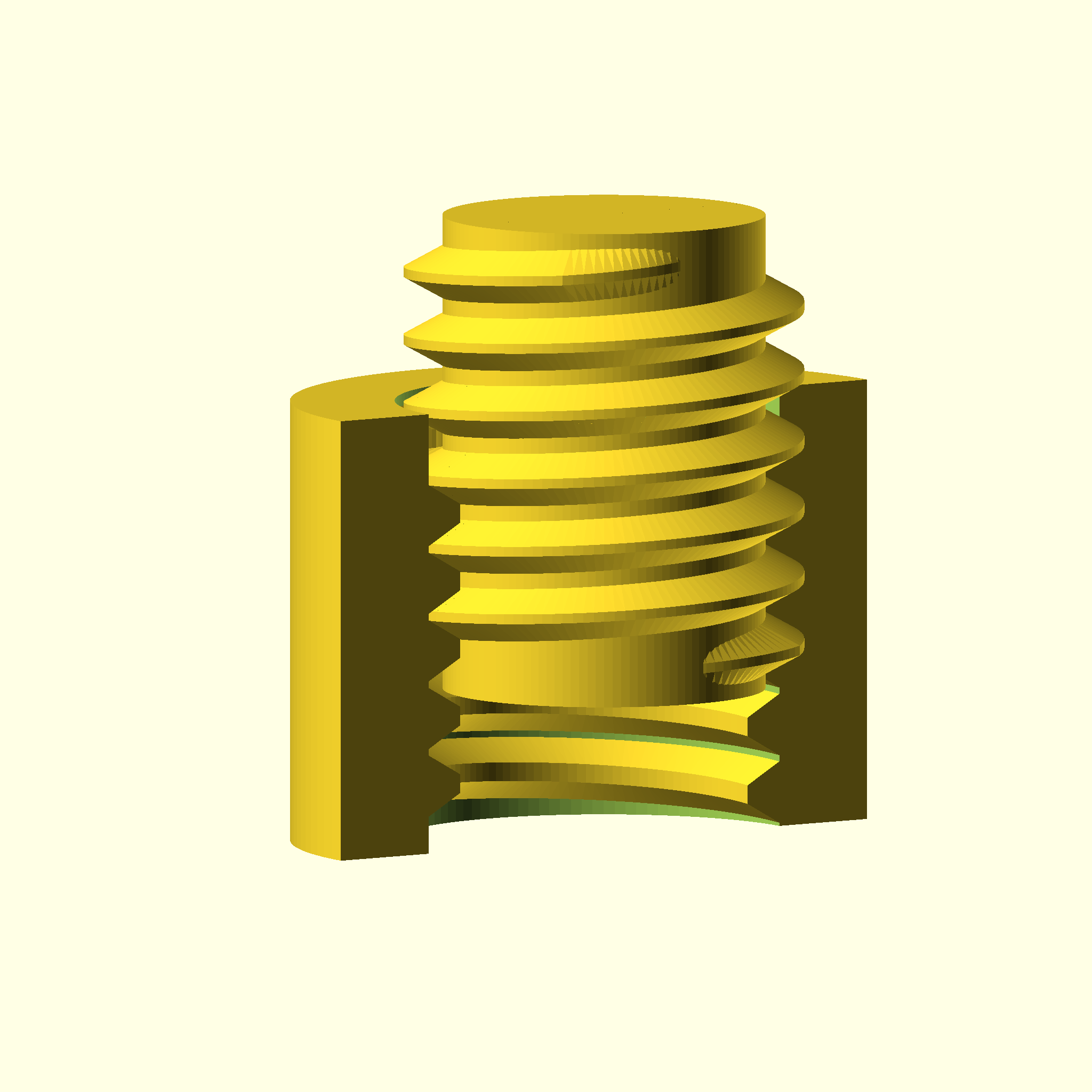

Yes, I am having the exact same issue. I used M60 as my experiment with this library. And have the exact same result. It seizes up after 1/2 turn.

I've cleaned the threads, even removed material manually to make sure the threads are all clean enough. Even shaved the threads down to allow tolerance. But it makes no difference. It's like the angles and spacing is all wrong, like when you try to mix incompatible thread types on metal nuts and bolts.

I've tried using the bolt function with nut, and bolt function with tap, and I get the exact same 1/2 turn seizing.

Could the author or maintainer please suggest why [karlkashofer] and myself are having these problems?

Thank you.

Hi ! Thanks for this fantastic and easy to use library ! I have just one problem, when i print a M12 nut and a M12 bolt they do not fit, the nut only screws on the bolt for one turn and then seizes up. I presume i need to add some more clearance ? How is that done properly ?

Thanks, Cheers, KK