Response from printer/AMS firmware team:

This is limited by hardware rather than a bug of slicer software.

The AMS instructions indicate that TPU is not supported.

We do have the option of TPU for the third material configuration of AMS at present, and this is unreasonable and we will remove in the later firmware.

And for some risky materials, we will add a hint to the user's selection.

We do have the option of TPU for the third material configuration of AMS at present, and this is unreasonable and we will remove in the later firmware.

And for some risky materials, we will add a hint to the user's selection.

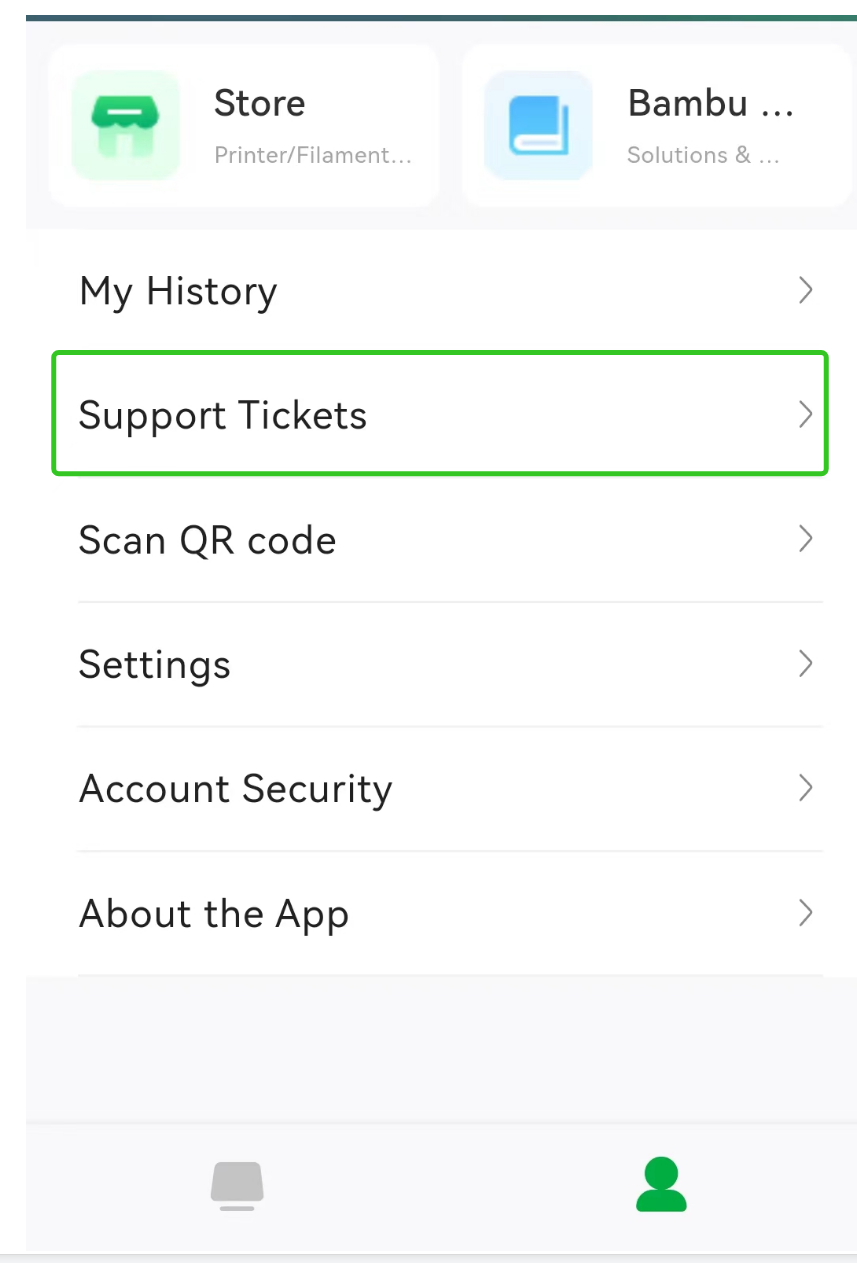

Describe the bug Printer refuses to print with TPU and AMS, even though I've never had an issue with many rolls of TPU

To Reproduce Load TPU into AMS Enter that information into AMS Try to print

Expected behavior Printer would allow you to print

I end up making fake profiles, called things like "TPU but faked as PLA" and then I have to remember what's really in the printer versus what I told it was in the printer to get around the restriction.

The other day I got a VERY nasty jam because the printer was printing TPU as thought it was PLA.

If TPU cannot be used in the AMS, do not list it as a choice, and have the AMS complain when you load it. Allowing materials the printer refuses to hit the right temperature for will very predictably lead to disasters.

Asking users to create fake profiles and forcing them to remember all the work-arounds necessarily means valid safety checks will not be performed. Telling your support staff to ask people to do this risks damage to the machine which Bambu should be responsible for.

It would be MUCH better to have an error pop up and advise you not to print, but allowing it, so profiles will match the capabilities of the machine.

I would STRONG recommend creating a "TPU > 92A" and a "TPU <92A" menu item on the AMS, and when someone selects TPU <92A, display a warning and refuse to use it, and/or give people an option to acknowledge the risk and do it anyways.

Or at least please respond to the topic and give some feedback on how to use the machine within the framework. As an engineer, it's bad practice to encourage users to have a bunch of fake profiles, work arounds, etc. The risk of damage to the machine is much higher with the current system.