Atmega/Arduino logic is 0-5V - so you can't directly control PWM driven spindle that expects 0-10V. That's why I was looking for 0-5V controller for my brushless 500W spindle. You need to create some additional translator 0-5V -> 0-10V. Example is here https://www.youtube.com/watch?v=VoeUr6CL9WA - sometime ago I even asked the question in comments about it.

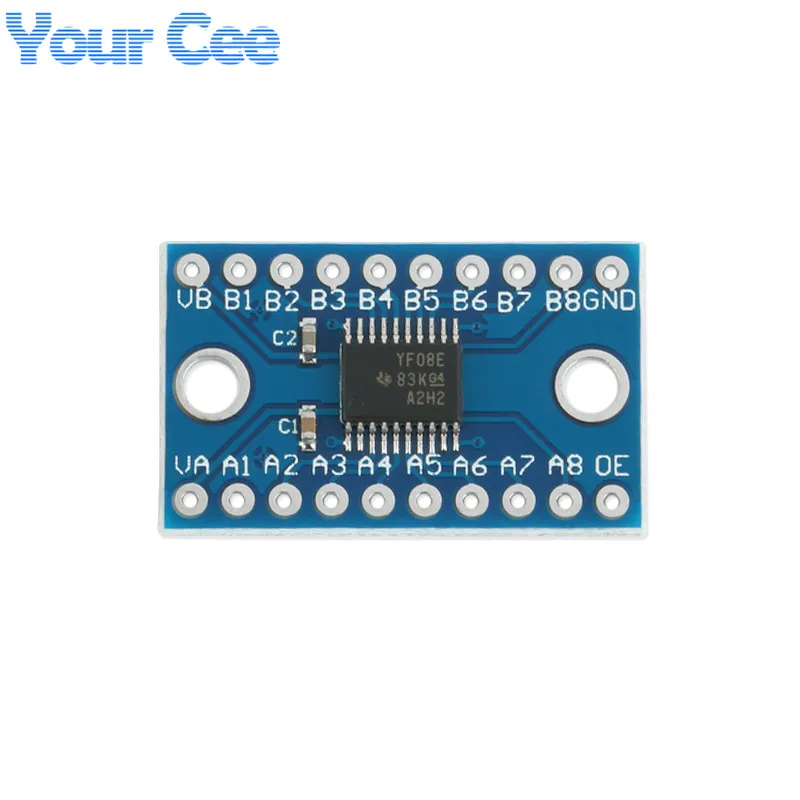

It's based on TXS0108E - all in one chip solution for 8 paths. This is just this chip, two caps and that's it. Then I've looked for something similar for 10V - and I haven't found (to buy). But there is, if I'm not mistaken, similar chip with higher voltage - this is the one I've mentioned before CD40109B-Q1.

This is just proposition, perhaps better, perhaps not - just something to consider if you wish.

It's based on TXS0108E - all in one chip solution for 8 paths. This is just this chip, two caps and that's it. Then I've looked for something similar for 10V - and I haven't found (to buy). But there is, if I'm not mistaken, similar chip with higher voltage - this is the one I've mentioned before CD40109B-Q1.

This is just proposition, perhaps better, perhaps not - just something to consider if you wish.

Can anyone on "Wiki" describe step by step how to connect and properly control the RPM via PWM-DAC 0-10V. Chinese spindle with inverter? So far, I've done it with the vfdPlugin-1.7.1 plugin in Mach3. I can't do this at GRBL connect and configure properly ... Please help!