You really are digging deep into this! It's great, almost wish my display also gave issues so that I can help with debugging :-)

Something else which could cause the jittery SPI signals are the interrupts. Maybe it's worth also trying to disable Timer6 (running at 10kHz) before the SPI transmission starts and enable it again after (create a critical section). Something like this:

void OLED_WR_Byte(uint8_t dat,uint8_t cmd)

{

uint8_t i;

LL_TIM_DisableCounter(TIM6);

if(cmd)

OLED_RS_H;

else

OLED_RS_L;

OLED_CS_L;

for(i=0;i<8;i++)

{

OLED_SCLK_L;

if(dat&0x80)OLED_SDIN_H;

else OLED_SDIN_L;

OLED_SCLK_H;

dat<<=1;

}

OLED_CS_H;

OLED_RS_H;

LL_TIM_EnableCounter(TIM6);

}

Looks like its at 300ms intervals.

Looks like its at 300ms intervals.

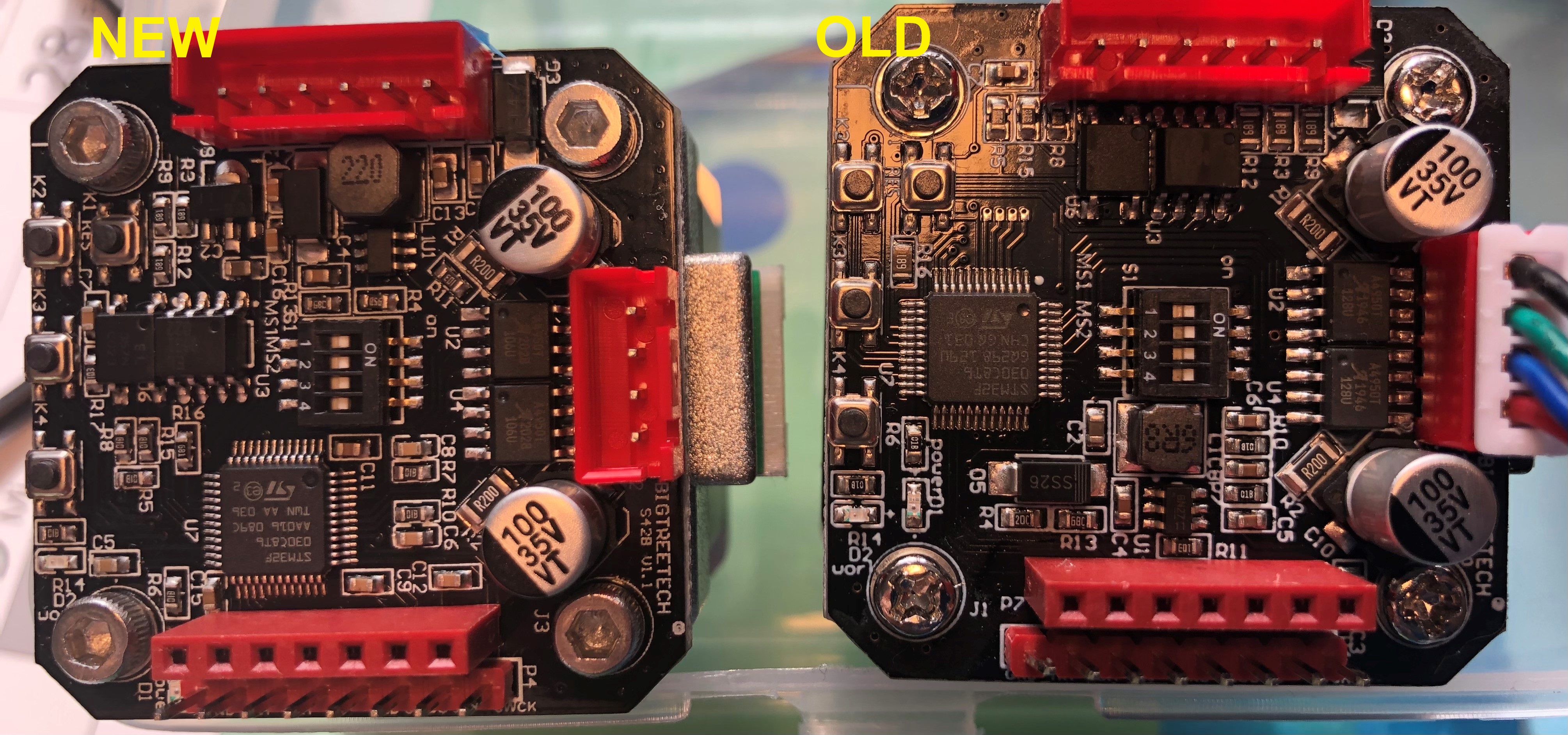

still in contact with btt for a solution

still in contact with btt for a solution  hope that's detailed enough

as I can read:

STM32F

030C8T6

AA094 079

TWN AA 02

ST

So it looks like a

hope that's detailed enough

as I can read:

STM32F

030C8T6

AA094 079

TWN AA 02

ST

So it looks like a

tall characters:

tall characters:

...after about 15hrs at 100mm/s even the best performing board failed and the OLED went black, the other just froze with artefacts..... and still no news from BTT which promised to send put replacement boards after sending a video to prove the problem...

...after about 15hrs at 100mm/s even the best performing board failed and the OLED went black, the other just froze with artefacts..... and still no news from BTT which promised to send put replacement boards after sending a video to prove the problem...

In the file oled.c, where the clock divide ration and oscillator frequency are initialized with the 0xD5 command. The parameter in the file is "80", but I think it should be the hex value "0x80". This might address some of the display instability issues.