@cgeudeker can you use nodal entity sets to predefine the nodes involved where this boundary condition occurs?

Also, I'm a bit confused by what exactly "material thickness" means above. I was thinking we're in a 2D plane strain problem, so cell "thickness" reminds me of the distance into/out of the page. It seems we actually need to consider the cell length or cell height (depending on the boundary orientation)?

Therefore, for a boundary condition along the model's bottom, for each node we want 1/2 the cell length for the left and right adjacent cell? Similar to a tributary area for a frame problem.

Please let me know if I'm not thinking about this correctly.

Describe the feature Kelvin-Voigt boundary equation requires adjacent material thickness in order to calculate the spring coefficient corresponding to the spring component of the boundary.

Describe alternatives

The original idea was to utilize cell length in order to calculate this value. For each node where the boundary condition is applied the cell length of each cell above the node that had the same material property would be summed to derive the thickness.

a. The problem I'm having with this approach is finding a way to determine which nodes, and therefor materials, are a part of which cells.

It could also be possible to calculate by iterating through the nodes from each boundary node to find the furthest distance. The iteration would start from a boundary mode and only find the furthest distance to the node with the same material id and x coordinate, or y depending on where its being applied.

a. The main problem with this approach is that it may just be unnecessary if the above approach is possible. b. I'm also unsure if it is possible to iterate through all the nodes within node.tcc.

Any suggestions for the above approaches or perhaps alternative approaches would be much appreciated.

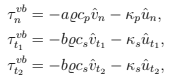

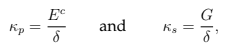

Additional context Kelvin Voigt boundary equations and relating equations for calculating the spring coefficient, where material thickness is represented by delta.