Thanks.

-

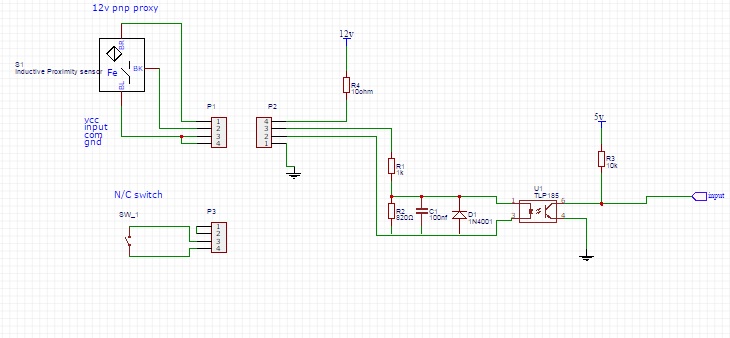

With BR=+ve, BL=0V, BK=Pull-up output normally closed, then P1 numbering is upside down.

-

Junctions appear to be lacking at the bottoms of R2, C1 and D1. It could be a bug in program rendering, but they are required if you intend to output it as a netlist to the PCB.

Minor: I don't think it'll make any difference to your shield, but you might wish to check the differences between "Earth", "Ground", "Chassis", "Common" and "0V" as well as named nodes such as "0VA" and 0VP" which are both 0V but for different sections. https://electronics.stackexchange.com/questions/108776/common-vs-ground

Just in case anyone else has the same problem: My ISP (Sky) had turned on its family filtering shield and blocked images (jpg, png) from Github (including yours) without me knowing, it just timed-out the images. Took a while to find out it was them. Filter is now off.

This is continuing on from the discussion on the GRBL limit switch issiue. https://github.com/gnea/grbl/issues/96

Hers where i got to on the limit switch wiring.