My assumptions were correct, I think. I went for the same surface and same settings from this:

To this:

And this toolpath output:

I'll be doing quite some 3D-milling in the coming weeks so I'll get to crash test this and see if any other bugs pop up by fixing this.

I get slow and incomplete 3D-milling toolpaths when calculating a fairly simple surface.

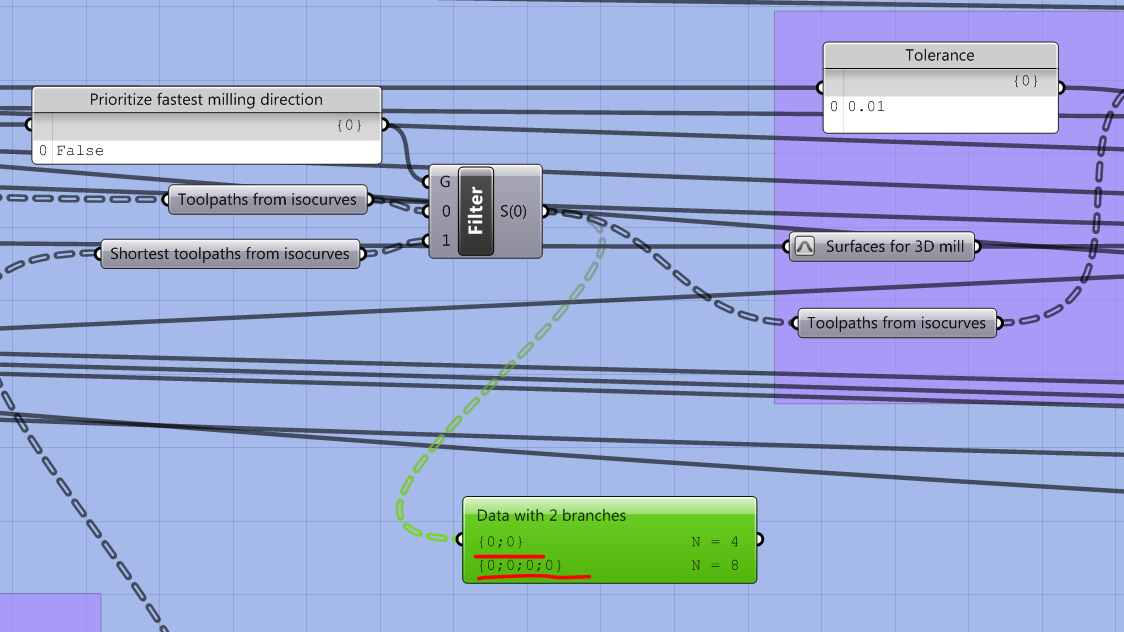

When investigating I think it might have something to do with the difference in tree branches inside the surface 3D mill component. Looking further into this.