Form the Readme in Edge: The G38.2 straight probe and G43.1/49 tool offset g-code commands are now supported. A simple probe switch must be connected to the Uno analog pin 5 (normally-open to ground). Grbl will report the probe position back to the user when the probing cycle detects a pin state change. (https://github.com/grbl/grbl/blob/edge/README.md). Whatever probe you design should be able to handle some over travel, the Z movement likely won't stop immediately. Some sort of spring arrangement would do.

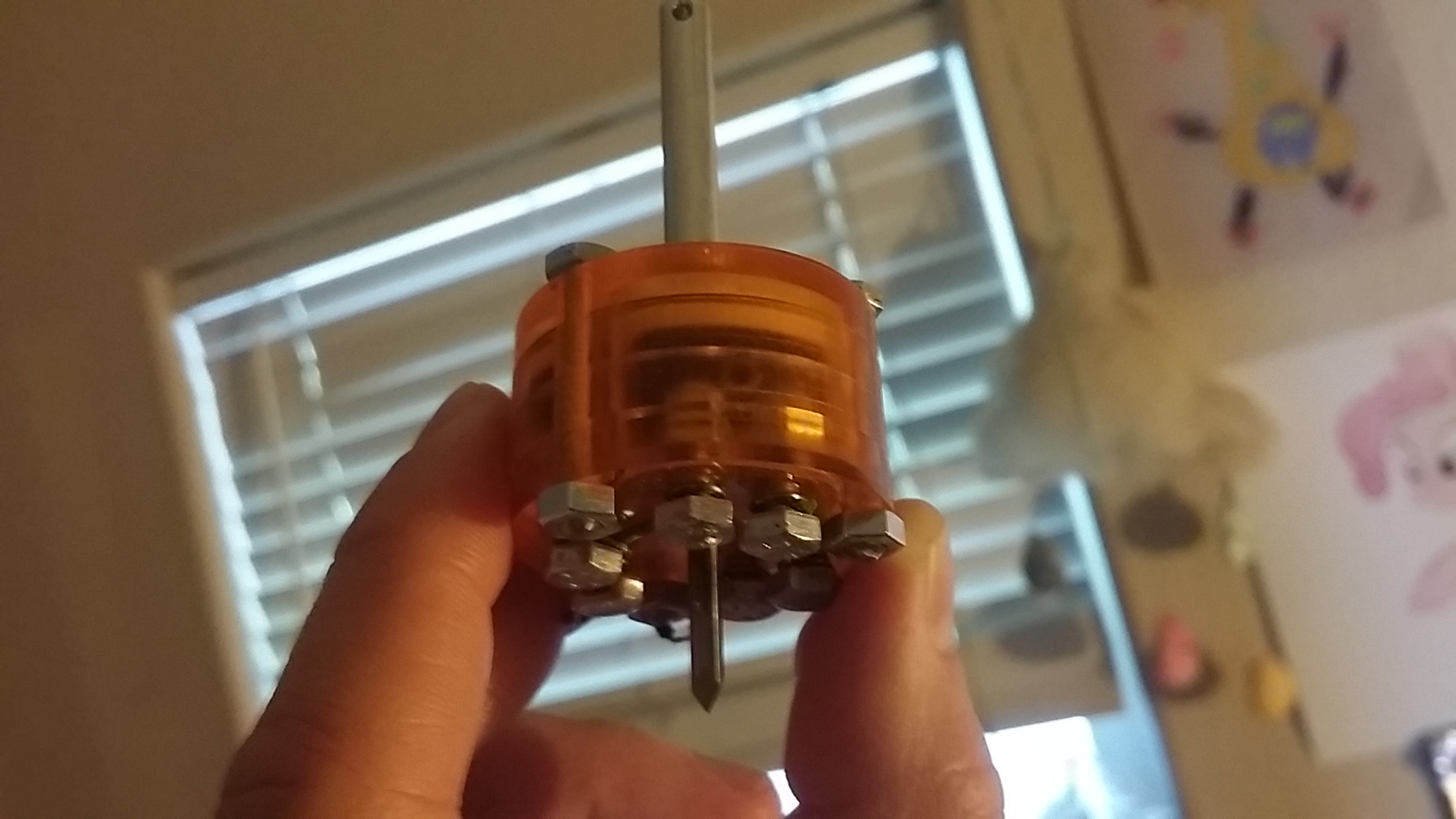

So the probe is anything that will take pin A5 to ground when it touches your object. The probe position is relative to machine 0. A typical porbe command might be G38.2 X20 Y15 Z-100 (in mm mode). You should set a slow feed rate , e.g. F20 (20mm/min). The G38 will move to X and Y, then Z axis will lower to -100 until the probe makes contact with your object, at which time movement stops. Grbl will report the machine position of the probe touch. E.g.

g38.2 x5y6z-100 [PRB:0.030,0.040,-0.645](this is what comes back from Grbl when the probe switches to ground) A typical cycle might look like: N01 set feedrate N02 G0 X(pos1) Y(pos2) N03 G38.2 Z-100 N04 G0 Z0 (retract probe) change to new pos1 and pos2 Repeat from N02

If using Mach3 or LinuxCNC, then this would work directly: http://www.scorchworks.com/Gcoderipper/gcoderipper.html. Grbl doesn't do variables (yet/never?) so you would need to write some sort of preprocessor to handle the operation based on the gcode that GcodeRipper outputs. But it can be done. Just run gcode ripper on one of your gcode files and look at its output, you will see the sequence of operations.

I had a quick look at the Wiki page but there were very little details about the probing feature in V0.9.

My questions are around: x How does the wiring work? x What kind of probes can be used? x General overview of the probing process...

Thanks.