The MK4 is printing at the moment for a few hours, but if you refer to the vertical distance, that's about 10mm from the tip of the nozzle to the underside of the bearing clamp. That's just an eyeball estimate. It's about 6mm vertically tip to cooling duct, and then a few more to the bearing clamp. I don't know if pictures get through here but I can get some if that is useful.

On Sat, May 20, 2023 at 9:31 AM Grégoire Saunier @.***> wrote:

@DesC21 https://github.com/DesC21 This is promising, 13.9mm seems to be more than the nozzle <-> X carriage distance. This is promising! And good news for the cable holder!

@akbiocca https://github.com/akbiocca do you think you could roughly estimate the space between nozzle and bottom of the X carriage?

— Reply to this email directly, view it on GitHub https://github.com/gregsaun/prusa_i3_bear_upgrade/issues/138#issuecomment-1555947279, or unsubscribe https://github.com/notifications/unsubscribe-auth/A3AIDK5DUMMZ2VMJWN26B4LXHDWW3ANCNFSM6AAAAAAWM2Y2GI . You are receiving this because you were mentioned.Message ID: @.***>

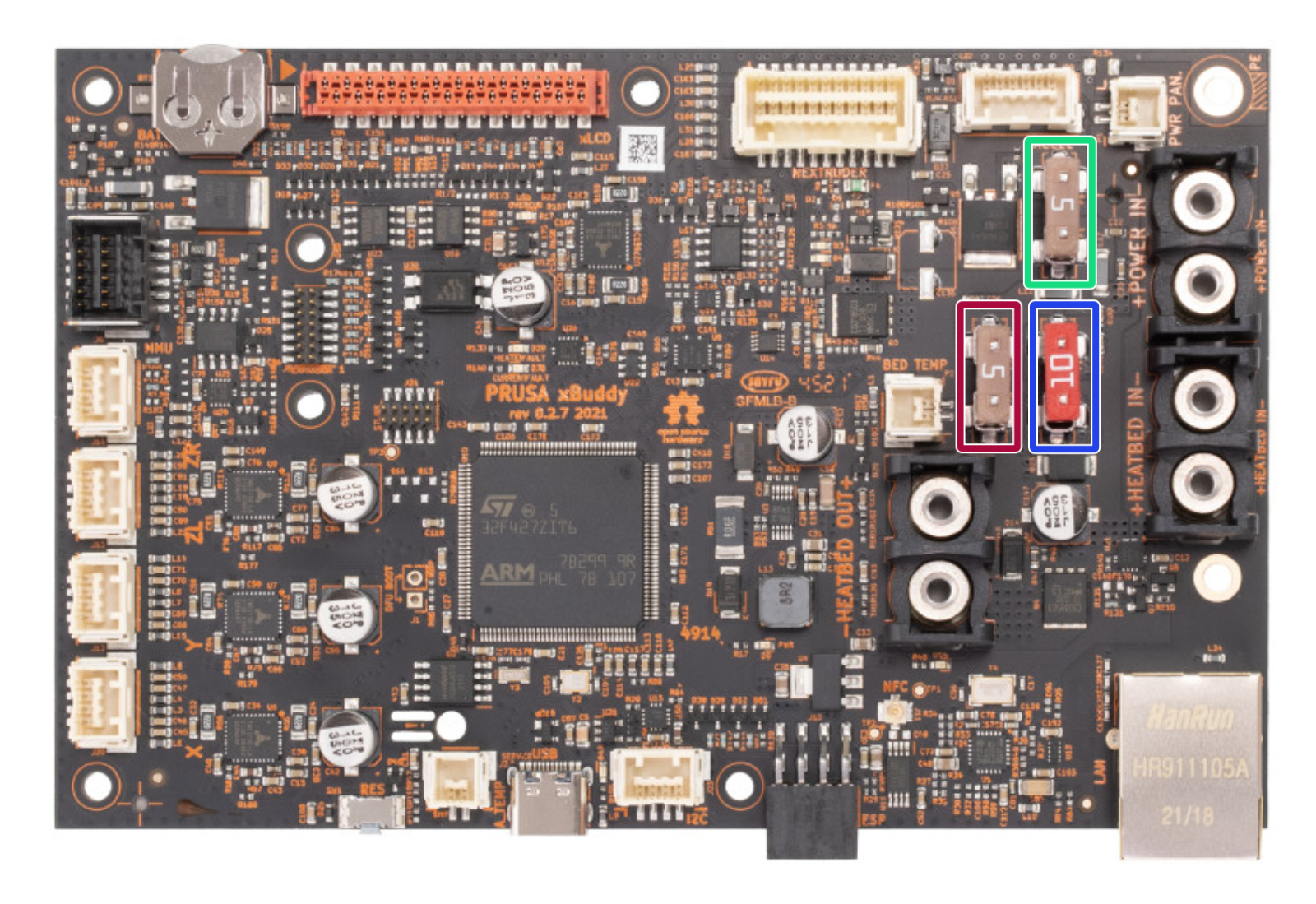

We could from this measure the ST32 chip, the ethernet connector, etc. I will see if I can find dimensions of the connectors too.

We could from this measure the ST32 chip, the ethernet connector, etc. I will see if I can find dimensions of the connectors too.

Hi, it's more a question: I have a bear 2.1 mk3s with bondtech extruder. Will the MK4 upgrade work outofthebox ? Or do I have to comeback to the original frame design and wait for bear 3.0 design ?