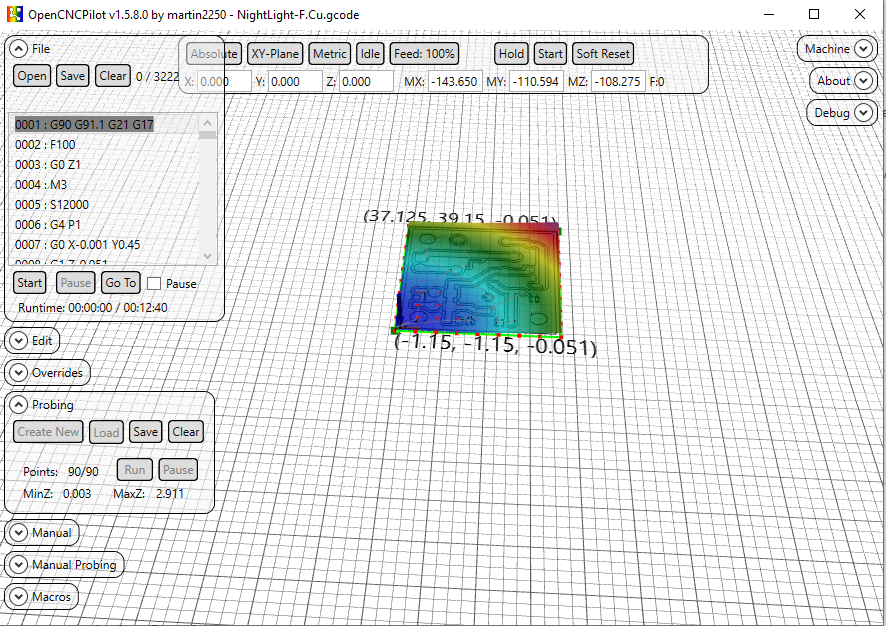

Hi Guru, "Points: 90/90" tells us, that your map is generated already. All 90 points of the map are obviously probed. Next after having done the probing you have to Apply the hight map to your gcode. You find the corresponding button in the "Edit" panel. After having applied the map you can "Start" etching (see "File" panel). Hope that helps.

Harald

I'll surely work on your comment. Since I don't have threaded road and nut for X and Y axis, I need to check how to avoid Anti-backlash. The CNC as whole doesn't shake or wobbles. But moves easily by hand. I need to work on that as well.

I'll surely work on your comment. Since I don't have threaded road and nut for X and Y axis, I need to check how to avoid Anti-backlash. The CNC as whole doesn't shake or wobbles. But moves easily by hand. I need to work on that as well.

Hi Martin,

First of all, thank you for this wonderful software. I was able install Grbl 1.1J and use OpenCNCPilot to move all 3 axis using manual mode as well as using Keyboard. Just wanted to make sure that I have met pre-requisites (grbl 1.1 and .NetFrameWork 5).

I was also able to utilize "Probe and set Zero" macro to check if my probing is functioning properly. It is working as expected.

I was trying to use the most awesome part of this software, Probing. But "Run" button is not getting enables. What I am missing here? Could you please throw some light on this. Attaching image of my Screen for your reference.

Thanks in Advance.

Regards, Guru