Hi delphir-com. Just my 2 cents: I strongly encourage you to switch to Teensy 3.1 ... I was on Arduino Pro Micro and like you I've found and fought with the memory barrier (29K). Now I'm working on a customized version of freeIMU-updates with SD data logging and additional functions specific to my needs. I'm now at 52 K and more important at least for me, the update frequency of calculations on sensors' data is at least 5 times higher than with the previous micro. Bye, Mario PS: thanks again to Mike for his wonderful work on the library

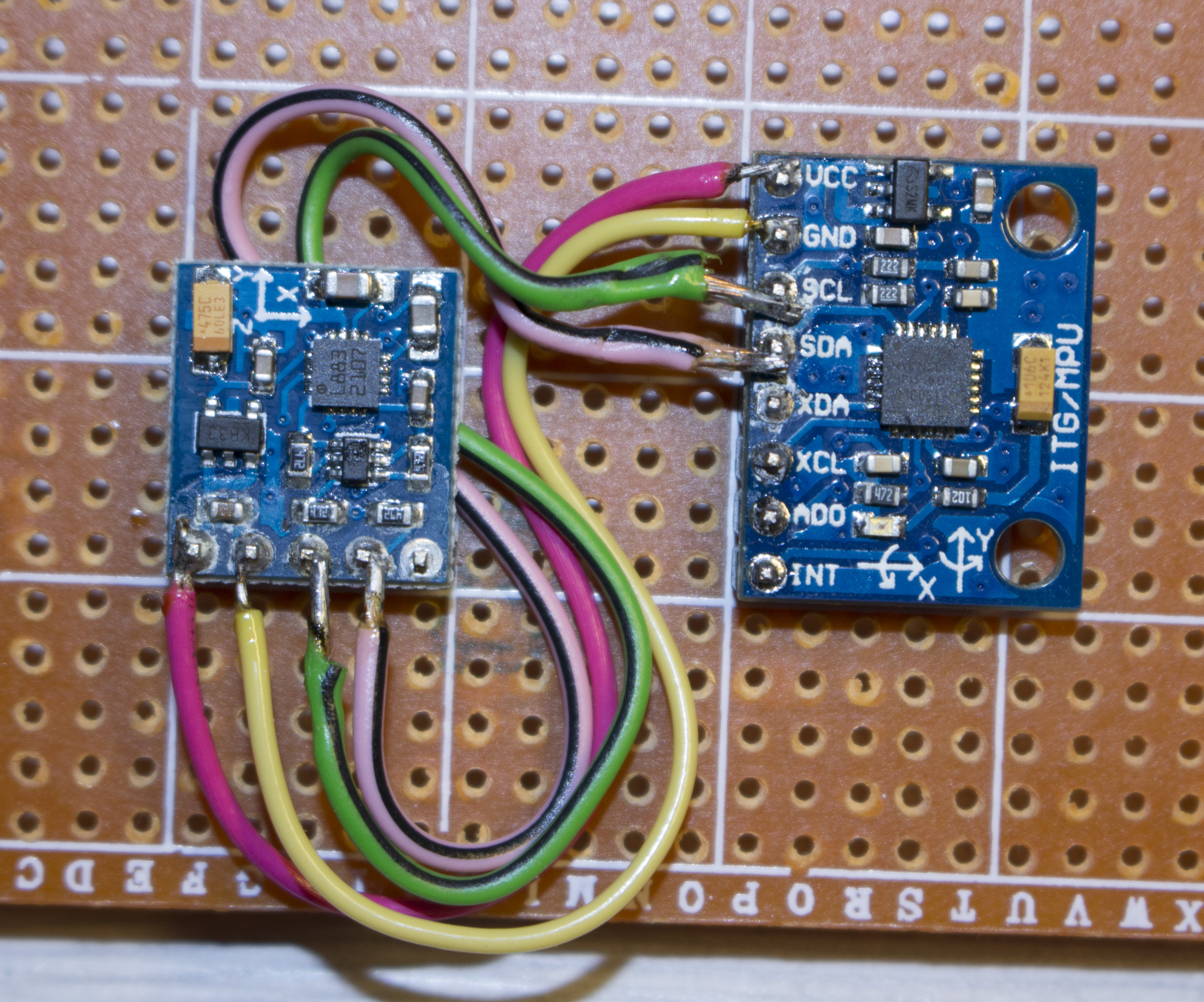

Hi guys! Nice discussion there. I`m working now on my own gimbal for panoramic photo shooting and decided to use sensors for excellent camera positioning. I have MPU6050, HMC5883L and Arduino Nano.. at first I thought that "sensor" part of my gimbal will be the easiest one as there are a plenty of samples in the internet, but once I started to work on it - I found this annoying yaw drift problem. So after a continuous googling I came to your github repo Mike and this thread :)

For now I have a very simple question: is it possible to upload your freeimu lib into an arduino nano without cutting the magnetometer code-part? the original freeimu lib easily fits into the Nano but it has a huge drift (sometimes even on pitch and roll). As I understand you have added a lot of optimisation/etc math algorithms to the lib which must help with Yaw, but this affected the size of the sketch :) Is there anything what can be shrinked from the lib wihout loosing it`s functionality for using with my hardware? For example you have mentioned about AHRS vs MARG algorithms and in my case looks like MARG will be better as I have a HMC5883L so in total with mpu6050 this will give 9DOF.. What else can be removed?

P.S. Thanks for your great job on FreeIMU lib, Mike. Without you it would be frozen in the 2012...

P.P.S. I`m also thinking now on buying Tennsy 3.1 for this proj to get rid of this memory problem, but I wanna be sure that I will not reach this Yaw problem again.. as before buying my current HW I have also checked the internet and found a lot of videos about "MPU6050 with FreeImu without Yaw drift" but nobody have mentioned that this is not the original FreeImu lib and that this changed one will require more memory :)