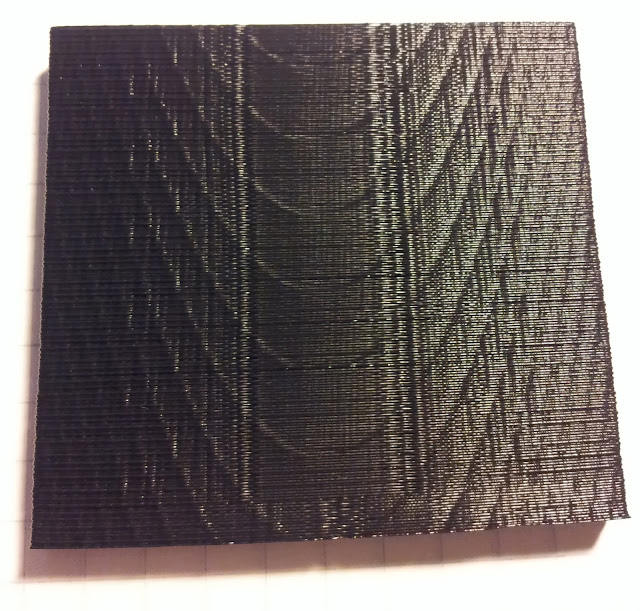

These artifacts are common in Delta printers. I'm afraid they stem from the motors themselves and are not due to the slicer. Used to have a delta for a long time and I used to see these kind of marks, although they would be more like concentric ovals. How does it look if you slice with a different software?

Example:

The wavy pattern on the yellow part extends from the very bottom to the very top, but it is nowhere to be found on the red part. I have no idea why this should be of course, but it is quite noticeable when you look closely.

The wavy pattern on the yellow part extends from the very bottom to the very top, but it is nowhere to be found on the red part. I have no idea why this should be of course, but it is quite noticeable when you look closely.

Version

142.0.Beta2

Operating system type + version

Win10/64 Home Ver. 1809 current build

3D printer brand

Atom2 + Marlin

Behavior

This is a bowl shaped piece with oval cross sections. These ridges appear on both sides of the print on opposite sides at the narrow ends.

It looks like there is a change in tolerance for generating the hotend GoTo points as it encounters a smaller radius of curvature. Is there some input parameter that can control this?