It might be helpful if the suspension under the poles was a single point (or rope), which would allow two people on either side of the rocket to be at a non-90 degree angle with respect to the rocket. I would forsee cases where one person has to navigate over brush more quickly then the opposite person, which would change the angle of the pole. A single point rope would allow it to pivot easily. On a side note, timber carriers do the swivel/pivot thing too... :)

The cradle should be designed such that the rocket won't move length-wise through the cradle. If it slides, it may hit the camera or the roll control canards on the cradle. A strap or something going over the top of the rocket body may do the trick.

I would also suggest having some kind of fast hook, or clip, or clamp type of quick connect method. If it only took a moment to do the final connect that would be great.

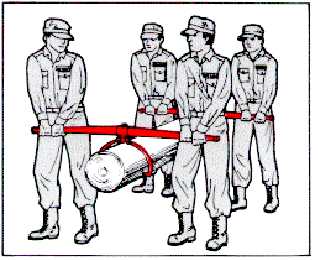

Carrying the rocket with 4 people is sufficient given they can easily maneuver around obstacles and hold the weight of the rocket in a comfortable way. The current rocket carrier which is now being redesigned as a work stand for the rocket was manageable for recovery but had unnecessary weight and size. The proposed design for the new method of carrying the rocket is with two poles with brackets on them that get strapped to the airframe of the rocket providing two perpendicular poles to the rocket for lifting. The poles should be long enough that each of the 4 people can adjust position laterally while walking. Making these poles light weight will also aid in reducing the overall carrying mass. A suggestion is to use light weight conduit pipe of about 1 to 1.5 inches in diameter with a wood support in the middle to cradle the rocket when it is strapped down. Similar in idea to timber carriers used for moving large logs.