Just saw: the first two coloumns in the prviuous post are Tool1. Sorry

In the meantime I added some more debug information

Offset-Values:

Tool1 Tool2 Z-Probe

X Offs Y Offs X Offs Y Offs X Offs Y Offs

0 0 -24 -4 -15 -23physical probing position is 24/23, should be 15/23 in my mind.

The Log lines begins with file - function (class) - than Variables and values.

Intermediate Lines: my comments

during homing X and Y

16:10:32.967 : PrTypeCart-OfficToTransf: officialX (0.00) + tOffsX (0.00) =0.00 officialY (-317.00) + tOffsY (0.00) =-317.00

16:10:32.967 : PrTypeCart-OfficToTransf: officialX (0.00) + tOffsX (0.00) =0.00 officialY (0.00) + tOffsY (0.00) =0.00

16:10:32.967 : PrTypeCart-OfficToTransf: officialX (0.00) + tOffsX (0.00) =0.00 officialY (0.00) + tOffsY (0.00) =0.00

next shows zProbe offsets

16:10:32.970 : zprobe-ZPHandler-vor closestAllowed: OffX=-15.00 OffY=-23.00

16:10:32.970 : zprobe-ZPHandler-nach closestAllowed: OffX=-15.00 OffY=-23.00

I think the "9" in officialX should not be there. 9 is probably the distance between Tool2Xoffset and ZProbeXOffset

16:10:32.971 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (0.00) =9.00 officialY (0.00) + tOffsY (0.00) =0.00

16:10:32.971 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (0.00) =9.00 officialY (0.00) + tOffsY (0.00) =0.00

16:10:32.971 : zprobe-ZPHandler-vor Aufruf setToolOffset: offsetX=15.00 OffY=23.00

Here the wrong X probing position (24) is calculated.

16:10:32.971 : setToolOffset: TOffXalt=0.00 TOffYalt=0.00 OxNeu=15.00 OyNeu=23.00 XYHomed! CurrPosX=9.00 CurrPosY=0.00 TempPosX (CurPosX+OxNeu-TOffXAlt)=24.00 TempPosY (CurPosY+OYNeu-TOffYAlt)=23.00

16:10:32.971 : PrTypeCart-OfficToTransf: officialX (24.00) + tOffsX (0.00) =24.00 officialY (23.00) + tOffsY (0.00) =23.00

16:10:33.747 : setToolOffset continued: TOffXNeu=15.00 TOffYNeu=23.00

16:10:33.747 : PrTypeCart-TransfToOfficials VOR OffsetManip: officialX (24.00 officialY (23.00

16:10:33.748 : PrTypeCart-TransfToOfficials NACH OffsetManip: officialX (9.00 officialY (0.00

16:10:33.751 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (15.00) =24.00 officialY (0.00) + tOffsY (23.00) =23.00

16:10:33.751 : PrTypeCart-TransfToOfficials VOR OffsetManip: officialX (24.00 officialY (23.00

16:10:33.751 : PrTypeCart-TransfToOfficials NACH OffsetManip: officialX (9.00 officialY (0.00

16:10:34.758 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (15.00) =24.00 officialY (0.00) + tOffsY (23.00) =23.00

16:10:35.571 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (15.00) =24.00 officialY (0.00) + tOffsY (23.00) =23.00

16:10:35.623 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (15.00) =24.00 officialY (0.00) + tOffsY (23.00) =23.00

16:10:36.081 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (15.00) =24.00 officialY (0.00) + tOffsY (23.00) =23.00

16:10:37.045 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (15.00) =24.00 officialY (0.00) + tOffsY (23.00) =23.00

16:10:37.076 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (15.00) =24.00 officialY (0.00) + tOffsY (23.00) =23.00

16:10:38.135 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (15.00) =24.00 officialY (0.00) + tOffsY (23.00) =23.00

16:10:38.136 : PrTypeCart-OfficToTransf: officialX (24.00) + tOffsX (15.00) =39.00 officialY (4.00) + tOffsY (23.00) =27.00

16:10:38.136 : setToolOffset: TOffXalt=15.00 TOffYalt=23.00 OxNeu=0.00 OyNeu=0.00 XYHomed! CurrPosX=24.00 CurrPosY=4.00 TempPosX (CurPosX+OxNeu-TOffXAlt)=9.00 TempPosY (CurPosY+OYNeu-TOffYAlt)=-19.00

16:10:38.137 : PrTypeCart-OfficToTransf: officialX (9.00) + tOffsX (15.00) =24.00 officialY (-19.00) + tOffsY (23.00) =4.00

16:10:39.038 : setToolOffset continued: TOffXNeu=0.00 TOffYNeu=0.00

16:10:39.039 : PrTypeCart-TransfToOfficials VOR OffsetManip: officialX (24.00 officialY (4.00

16:10:39.039 : PrTypeCart-TransfToOfficials NACH OffsetManip: officialX (24.00 officialY (4.00

16:10:39.039 : PrTypeCart-OfficToTransf: officialX (24.00) + tOffsX (0.00) =24.00 officialY (4.00) + tOffsY (0.00) =4.00

16:10:39.730 : PrTypeCart-TransfToOfficials VOR OffsetManip: officialX (24.00 officialY (4.00

16:10:39.731 : PrTypeCart-TransfToOfficials NACH OffsetManip: officialX (24.00 officialY (4.00

16:10:39.731 : PrTypeCart-OfficToTransf: officialX (24.00) + tOffsX (0.00) =24.00 officialY (4.00) + tOffsY (0.00) =4.00

16:10:39.732 : PrTypeCart-OfficToTransf: officialX (24.00) + tOffsX (0.00) =24.00 officialY (4.00) + tOffsY (0.00) =4.00Hope this helps a bit!

Hi,

trying to configure offset values for following configuration at a cartesian printer and came to varying ZProbing positions: This should be the final setup X to the right, Y up, Tool1 is at the lower left edge of the printable area:

For test as a first step I used only negative offsets, because all tools and ZProbe are all reachable. So the test setup looks like this:

Basic Parameters around offset topic: ENDSTOP_<X/Y>_BACK_ON_HOME = 0/0 <X/Y>min = 0/0 ZHOME<X/Y>_POS = 0/0

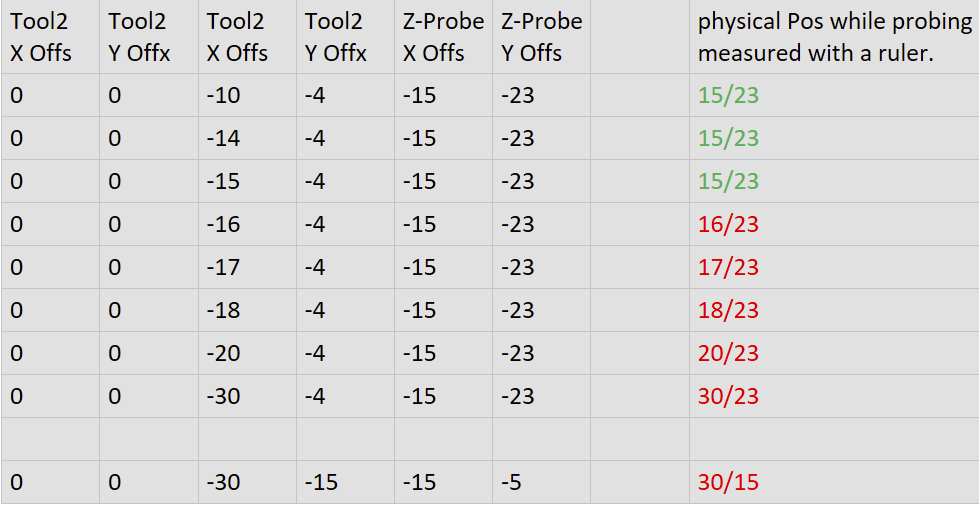

The issue is, that the probing position is not allways the position specified by Z-Probe<X/Y>Offset. Made a series of offset values, here is a screenshot of my test table:

My interpretation: The X position, which is moved to for probing, is the mathematical smaller value of Tool2 X offset and ZProbe X offset The Y position, which is moved to for probing, is the mathematical smaller value of Tool2 Y offset and ZProbe Y offset

I already added log information in motionLevel1.cpp, void Motion1::setToolOffset(float ox, float oy, float oz) The transmittel values ox and oy seem to be wrong:

Did I configure something wrong?