Hi Agent6-6-6,

When you create a CustomSection, you need to make sure the control point you define is within the region of the CustomSection and not on an edge, as this can confuse the mesh generator. All the built-in sections automatically choose a control point within the section, but the CustomSection class requires user input for the control point. I will update the docs to make this clear as I don't think it's explained well enough - thanks for pointing this out!

I have modified a few lines of your code with the updated control points and a few different mesh sizes to illustrate that the intended result is obtained:

control_points1 = [[weld_leg_size / 3, weld_leg_size / 3]]

control_points2 = [[-weld_leg_size / 3, weld_leg_size / 3]]

control_points3 = [[weld_leg_size / 3, -weld_leg_size / 3]]

control_points4 = [[-weld_leg_size / 3, -weld_leg_size / 3]]

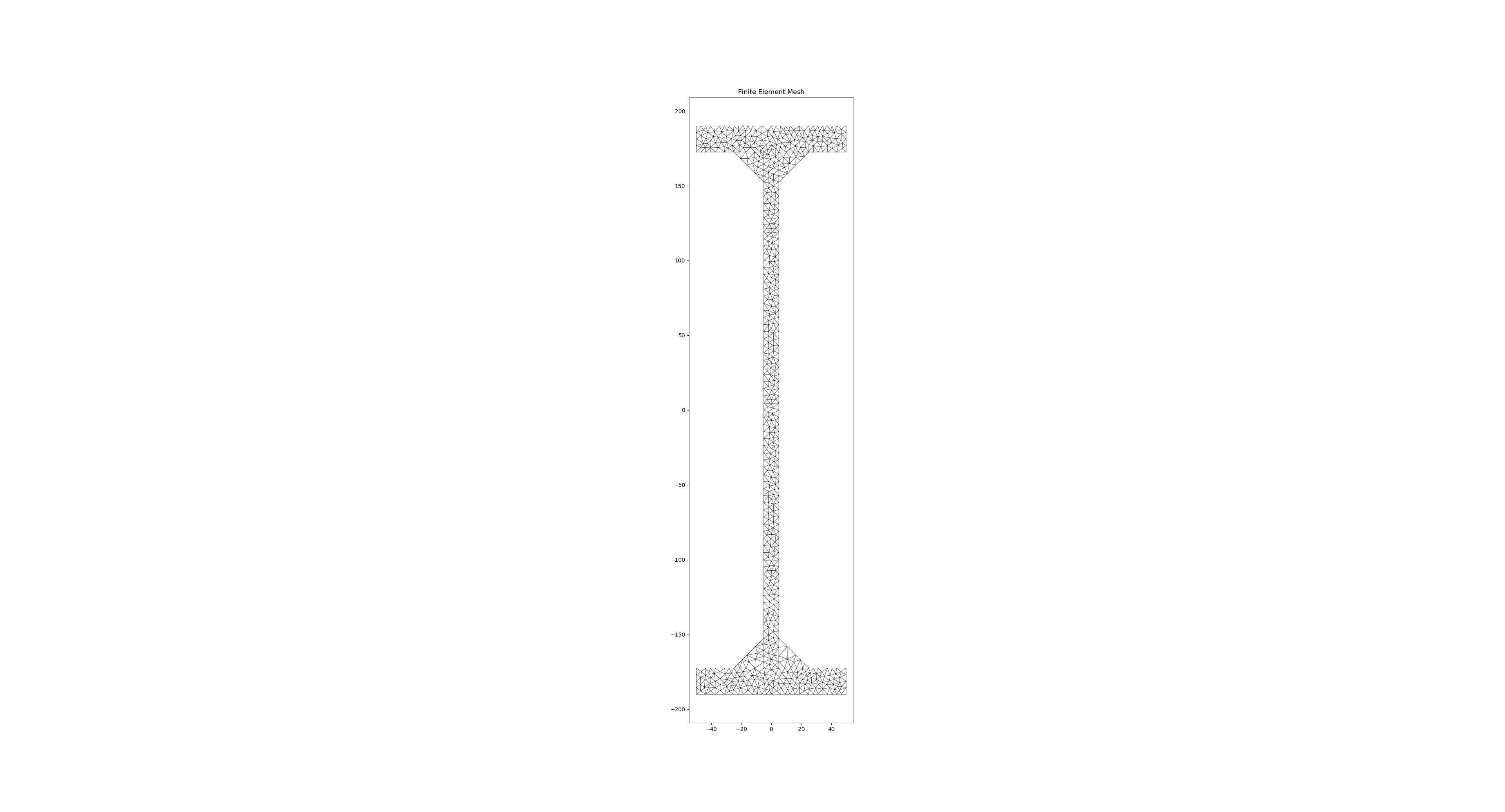

mesh = geometry.create_mesh(mesh_sizes=[100, 5, 10, 2, 1])Here's a few screenshots illustrating the intended results:

Also, thanks for the kind words in the additional context :wink:

Let me know if you have any other questions!

Robbie

Describe the bug For a section made up of multiple CustomSections only the last mesh size defined seems to be being applied to all custom sections (with the others not being taken into account). Not sure if I am interpreting how it should be working incorrectly or not.

To Reproduce Steps to reproduce the behavior: Run the following, play with mesh sizes and see that first 4 have no effect on the mesh being generated.

Expected behavior Based on the above code and based on examples in the readme/readthedocs for built up sections I would have expected that the I section and first three triangular areas representing welds would have a different mesh size to the last triangular area.

Screenshots Results showing similar 10 mesh for all customsection elements

Desktop (please complete the following information):

Additional context Excellent tool by the way!