But I would highly suggest you do not try to use driver definitions that do not match your hardware. You were setting all kinds of bits unintentionally. The code below works but is not how you should do it. The Release v1 branch supports the TMC2300 so I would suggest using that instead. I'll try to port this over to that branch when I have the time.

#include <Arduino.h>

#include <TMCStepper.h>

#define STALL_VALUE 60// [0... 255]

#define EN_PIN 8 // Enable pin

#define VIO_PIN 19 // Driver VIO pin used for resetting the driver

#define SW_RX 2 // SoftwareSerial receive pin

#define SW_TX 3 // SoftwareSerial transmit pin

//#define SERIAL_PORT 0 // HardwareSerial port

#define DRIVER_ADDRESS 0b00 // TMC2209 Driver address according to MS1 and MS2

#define DIAG_PIN 6 // diag input

#define R_SENSE 0.11f // Match to your driver

TMC2209Stepper driver(SW_RX, SW_TX, R_SENSE, DRIVER_ADDRESS);

using namespace TMC2209_n;

void setup() {

pinMode(EN_PIN, OUTPUT);

pinMode(DIAG_PIN, INPUT);

pinMode(VIO_PIN, OUTPUT);

digitalWrite(EN_PIN, LOW);

digitalWrite(EN_PIN, HIGH);

digitalWrite(VIO_PIN, LOW);

delay(500);

digitalWrite(VIO_PIN, HIGH);

Serial.begin(115200); // Init serial port and set baudrate

while (!Serial); // Wait for serial port to connect

Serial.println("\nStart...");

driver.beginSerial(19200);

driver.toff(1);

driver.irun(20);

driver.microsteps(128); //microsteps 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128 1/256

driver.TCOOLTHRS(0xFFFFF); // 20bit max

driver.SGTHRS(50);

Serial.print("\nTesting connection...");

uint8_t result = driver.test_connection();

if (result) {

Serial.println("failed!");

Serial.print("Likely cause: ");

switch (result) {

case 1: Serial.println("loose connection"); break;

case 2: Serial.println("no power"); break;

}

Serial.println("Fix the problem and reset board.");

// We need this delay or messages above don't get fully printed out

delay(100);

abort();

}

Serial.println("OK");

driver.VACTUAL(15120); // motor speed

}

void loop() {

Serial.print(100 * digitalRead(DIAG_PIN)); //check for stall

Serial.print("\t");

Serial.print(driver.SG_RESULT()); // Motor load

Serial.print("\n ");

}

Hi,

I'm having an issue with my setup. I want to use a TMC2300 to detect a stall using StallGuard, and then use Coolstep to adapt the current when in use in order to save power since my setup is running on batteries. But I have reached a standstill in my progress.

I have configured a stall, and when I compare it to SG_RESULT, and when SG_VALUE ≤ SGTHRS*2, the motor does not stop, and the DIAG pin does not react. I have tried different configurations, microsteps, speed, Stall values, ect, but no matter the config the driver will not detect a stall. I can read values on the driver with no issue.

Another issue; The motor will not run before I have disconnected and reconnected power from the power supply

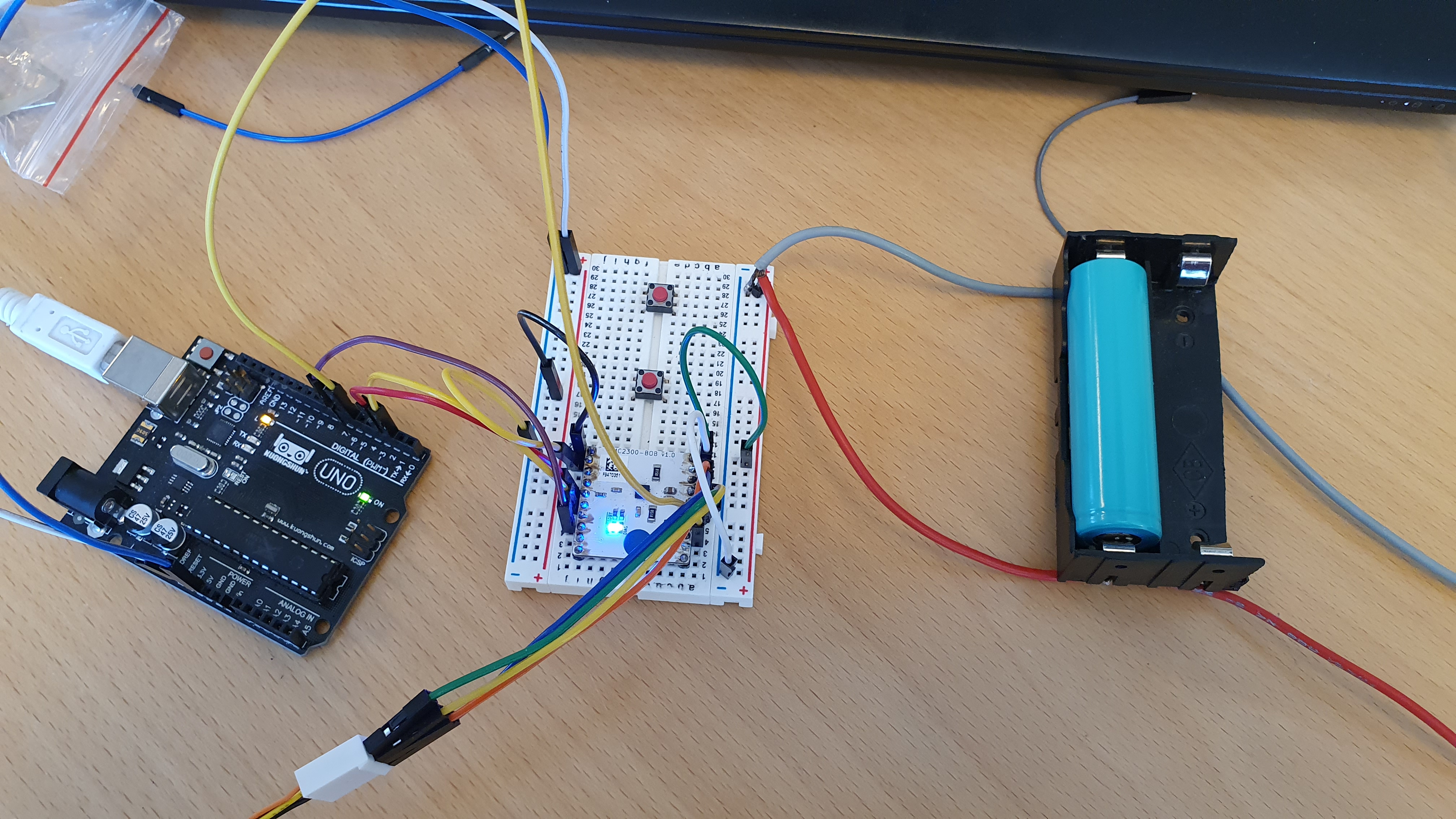

I am using an Arduino uno, PM35S-048 motor, TMC2300, 12V battery-power supply.

My test code is:

my test setup: Note: DIAG is NOT on