Open SAE J1939

SAE J1939 is a protocol for shaping the CAN-bus message in a specific way that suits industrial vehicles such as tractors, machinery, trucks and more.

SAE J1939 is a very easy protocol to use, but there is a lack of information about SAE J1939, due to the cost of the protocol document, available how to shape a CAN-bus message according to SAE J1939 protocol standard. So therefore I’m writing a SAE J1939 protocol available for free to use on any embedded systems such as STM32, Arduino, AVR, PIC etc or PC.

To learn to build on this project, you need first to understand SAE J1939. I have written this project in C language because C is an industry standard. The C language dialect I have chosen is ANSI C (C89) and I don't use dynamical memory allocation in this library. So it will work with MISRA C standard.

With this library, you can communicate with valves, engines, actuators, machinery, hardware and all other things that are suitable for heavy industrial mobile applications. I have build up a basic structure of the project and I hope that other users will send pull request of their C code for extra functionality to SAE J1939 standard because SAE J1939 is a huge standard.

Looking for C CANopen library for embedded systems? https://github.com/DanielMartensson/Easy-CANopen

Looking for a C++ GUI framework that uses Open SAE J1939 over the USB? https://github.com/DanielMartensson/GoobySoft

Looking for a C STM32 project with Open SAE J1939? https://github.com/DanielMartensson/STM32-PLC

Getting started

The first thing you need to know is to read my own PDF document of Open SAE J1939 inside the Documentation folder.

Learn the structure of the project, else you won't be able to understand SAE J1939.

After you have got a basic understanding of the project, you are able to build on it. Keep it simple and follow the

SAE J1939 standard!

After you have understand the structure of the project, then select processor choice in Hardware -> Hardware.h file.

Here you can select for example STM32, Arduino, PIC, AVR etc. or if you want to run it on PC first, then select PROCESSOR_CHOICE 0 and run some examples.

That's the debugging mode for internal CAN feedback.

How to use the project

- Step 1: Download this repository

- Step 2: Go to

Hardware -> Hardware.hand select your processor, if it's not available, please write code for it and send me a pull request - Step 3: Copy over the

Srcfolder to your project folder inside your IDE. RenameSrcto for exampleOpen SAE J1939. That's a good name. - Step 4: Use the

Examples -> Open SAE J1939 -> Main.txtexample as your initial starting code for a SAE J1939 project.

/*

* Main.c

*

* Created on: 16 juli 2021

* Author: Daniel Mårtensson

*/

#include <stdio.h>

/* Include Open SAE J1939 */

#include "Open_SAE_J1939/Open_SAE_J1939.h"

/* Include ISO 11783 */

#include "ISO_11783/ISO_11783-7_Application_Layer/Application_Layer.h"

void Callback_Function_Send(uint32_t ID, uint8_t DLC, uint8_t data[]) {

/* Apply your transmit layer here, e.g:

* uint32_t TxMailbox;

* static CAN_HandleTypeDef can_handler;

* This function transmit ID, DLC and data[] as the CAN-message.

* HardWareLayerCAN_TX(&can_handler, ID, DLC, data, &TxMailbox);

*

* You can use TCP/IP, USB, CAN etc. as hardware layers for SAE J1939

*/

}

void Callback_Function_Read(uint32_t* ID, uint8_t data[], bool* is_new_data) {

/* Apply your receive layer here, e.g:

* CAN_RxHeaderTypeDef rxHeader = {0};

* static CAN_HandleTypeDef can_handler;

* This function read CAN RX and give the data to ID and data[] as the CAN-message.

* if (HardWareLayerCAN_RX(can_handler, &rxHeader, ID, data) == STATUS_OK){

* *is_new_data = true;

* }

*

* You can use TCP/IP, USB, CAN etc. as hardware layers for SAE J1939

*/

}

/* This function reads the CAN traffic */

void Callback_Function_Traffic(uint32_t ID, uint8_t DLC, uint8_t data[], bool is_TX) {

/* Print if it is TX or RX */

printf("%s\t", is_TX ? "TX" : "RX");

/* Print ID as hex */

printf("%08X\t", ID);

/* Print the data */

uint8_t i;

for (i = 0U; i < DLC; i++) {

printf("%X\t", data[i]);

}

/* Print the non-data */

for (i = DLC; i < 8U; i++) {

printf("%X\t", 0U);

}

/* New line */

printf("\n");

}

/* Apply your delay here */

void Callback_Function_Delay(uint8_t delay){

/* Place your hardware delay here e.g HAL_Delay(delay); for STM32 */

}

int main() {

/* Create our J1939 structure */

J1939 j1939 = { 0 };

/*

* Callbacks can be used if you want to pass a specific CAN-function into the hardware layer.

* All you need to do is to enable INTERNAL_CALLLBACK inside hardware.h

* If you don't want to have the traffic callback, just set the argument as NULL.

* If you don't want any callback at all, you can write your own hardware layer by selecting a specific processor choice at hardware.h

*/

CAN_Set_Callback_Functions(Callback_Function_Send, Callback_Function_Read, Callback_Function_Traffic, Callback_Function_Delay);

/* Load your ECU information */

Open_SAE_J1939_Startup_ECU(&j1939);

/* SAE J1939 process */

bool run = true;

while (run) {

/* Read incoming messages */

Open_SAE_J1939_Listen_For_Messages(&j1939);

/* Your application code here */

}

/* Save your ECU information */

Open_SAE_J1939_Closedown_ECU(&j1939);

return 0;

}See the examples in Examples -> SAE J1939 how to change the address, NAME or identifications for your ECU.

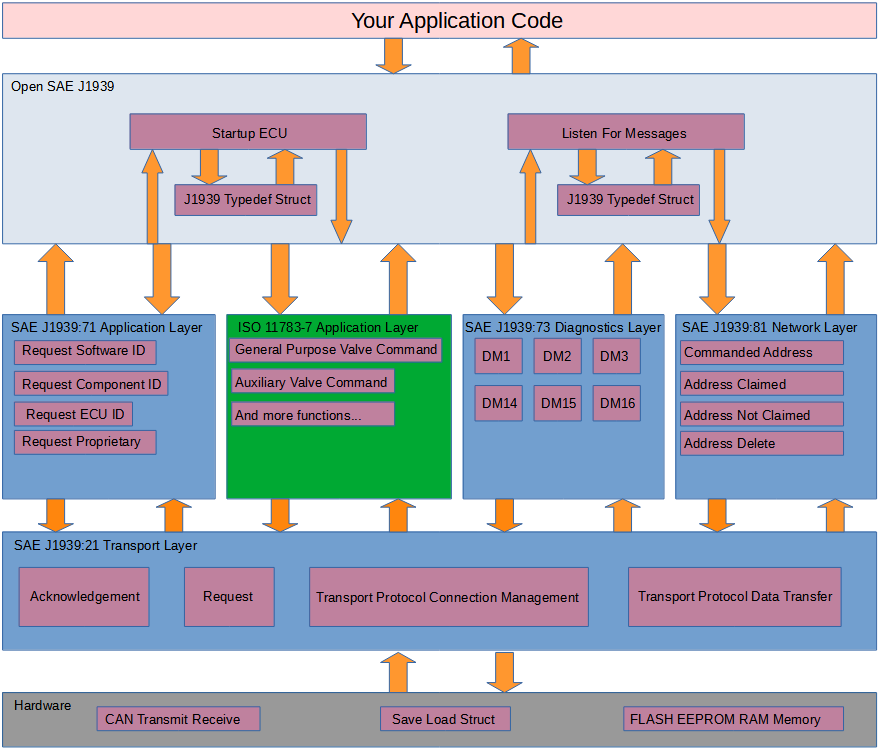

The structure of the project

A Working example how the structure of Open SAE J1939 is done

This flow chart in code how Open SAE J1939 library is working. This example demonstrates how to send a request and get an answer.

- Step 1:

ECU Xis going to send aPGNtoECU Y. InterpretPGNas a function code. https://github.com/DanielMartensson/Open-SAE-J1939/blob/4297cff44107e5278f120243cb9a611eafe8c42f/Src/SAE_J1939/SAE_J1939-71_Application_Layer/Request_ECU_Identification.c#L18-L20 - Step 2:

ECU Yis going to read thatPGNmessage fromECU X. https://github.com/DanielMartensson/Open-SAE-J1939/blob/4297cff44107e5278f120243cb9a611eafe8c42f/Src/Open_SAE_J1939/Listen_For_Messages.c#L18-L32 - Step 3: The

PGNfunction code will be interpreted byECU Y. https://github.com/DanielMartensson/Open-SAE-J1939/blob/678473c13cb7eb5fe46d5aac30a53efad4ccefd9/Src/SAE_J1939/SAE_J1939-21_Transport_Layer/Request.c#L20-L52 - Step 4: The

PGNfunction code is now interpreted asECU IdentificationbyECU Y. ThenECU Yis going to broadcast theECU Identificationto allECUs.- Step 4.1.1: For 1 package message,

ECU Yis going to broadcast theECU Identification. https://github.com/DanielMartensson/Open-SAE-J1939/blob/678473c13cb7eb5fe46d5aac30a53efad4ccefd9/Src/SAE_J1939/SAE_J1939-71_Application_Layer/Request_ECU_Identification.c#L26-L42 - Step 4.1.2:

ECU Xread the response fromECU Ybecause theECU Identificationis broadcasted. https://github.com/DanielMartensson/Open-SAE-J1939/blob/8faf1a542b291cb2ff71f20fceb941bb6113127b/Src/Open_SAE_J1939/Listen_For_Messages.c#L61-L62 - Step 4.2.1: For Multi Package Message, the control byte can either be BAM or RTS. BAM is only used if you send to all

ECUse.g address0xFF = 255. But if the control byte is RTS, e.g address is not0xFF, thenECU Yis going to send a RTS and listen for a CTS response byECU X. RTS is a question for "Let me know when I can transmit the message?" and CTS is responseNow you can transmit the message to me. https://github.com/DanielMartensson/Open-SAE-J1939/blob/678473c13cb7eb5fe46d5aac30a53efad4ccefd9/Src/SAE_J1939/SAE_J1939-71_Application_Layer/Request_ECU_Identification.c#L44-L58 - Step 4.2.2: If

ECU Yis sending a RTS, thenECU Xwill read the RTS and response with CTS back toECU Yhttps://github.com/DanielMartensson/Open-SAE-J1939/blob/678473c13cb7eb5fe46d5aac30a53efad4ccefd9/Src/SAE_J1939/SAE_J1939-21_Transport_Layer/Transport_Protocol_Connection_Management.c#L22-L26 - Step 4.2.3: Once

ECU Yhas received the CTS, then it going to transmit the data, in this caseECU Identification, back toECU X. https://github.com/DanielMartensson/Open-SAE-J1939/blob/678473c13cb7eb5fe46d5aac30a53efad4ccefd9/Src/SAE_J1939/SAE_J1939-21_Transport_Layer/Transport_Protocol_Connection_Management.c#L29-L31 - Step 4.2.3: Once

ECU Yis sending package after package... https://github.com/DanielMartensson/Open-SAE-J1939/blob/8faf1a542b291cb2ff71f20fceb941bb6113127b/Src/SAE_J1939/SAE_J1939-21_Transport_Layer/Transport_Protocol_Data_Transfer.c#L84-L105 - Step 4.2.4: Then

ECU Xis recieving each package and building up the message by knowing thePNGfunction code. https://github.com/DanielMartensson/Open-SAE-J1939/blob/8faf1a542b291cb2ff71f20fceb941bb6113127b/Src/SAE_J1939/SAE_J1939-21_Transport_Layer/Transport_Protocol_Data_Transfer.c#L19-L48 And then finally implement the message. https://github.com/DanielMartensson/Open-SAE-J1939/blob/8faf1a542b291cb2ff71f20fceb941bb6113127b/Src/SAE_J1939/SAE_J1939-21_Transport_Layer/Transport_Protocol_Data_Transfer.c#L66-L68

- Step 4.1.1: For 1 package message,

SAE J1939 functionality

- SAE J1939:21 Transport Layer

- Acknowledgement

- Request

- Transport Protocol Connection Management with BAM, CTS, RTS and EOM

- Transport Protocol Data Transfer

- SAE J1939:71 Application Layer

- Request Component Identification

- Request ECU Identification

- Request Software Identification

- Request Proprietary A

- Request Proprietary B

- SAE J1939:73 Diagnostics Layer

- DM1

- DM2

- DM3

- DM14

- DM15

- DM16

- SAE J1939:81 Network Management Layer

- Address Claimed

- Commanded Address

- Address Not Claimed

- Delete Address

Extra functionality

- ISO 11783 Tractors And Machinery For Agriculture And Forestry

- ISO 11783-7 Implement Messages Application Layer

- Auxiliary Valve Command

- Auxiliary Valve Estimated Flow

- Auxiliary Valve Measured Position

- General Purpose Valve Command

- General Purpose Valve Estimated Flow

- ISO 11783-7 Implement Messages Application Layer

Questions and answers

- Q: Can this library be used with

C++?- A: Yes it can be used with

C++

- A: Yes it can be used with

- Q: I want to build on this library, what should I do?

- A: First you need to know

ANSI C (C89)and bitwise operations. Then you need to understand theSAE J1939:21 Transport Layerstructure. Don't forget to update the PDF with your new functionality.

- A: First you need to know

- Q: Can I use this on my Arduino?

- A: Yes, this

Ccode is 100% pureCcode and only usingCstandard library and also the code does not take account of what hardware you are using.

- A: Yes, this

- Q: Do I need to install the library for to use the library?

- A: No, just copy over the

.cand.hfiles to your project and compile. I have used this with QT framework.

- A: No, just copy over the

- Q: This project is quite old now and not so much updates, is it still worth to use it?

- A: Yes, this library only updates when I or other includes more functionality from SAE J1939. The reason why I wrote this in

ANSI C (C89)is because it's an industry standard and you will always be able to compile this library and use it on all systems.

- A: Yes, this library only updates when I or other includes more functionality from SAE J1939. The reason why I wrote this in

- Q: What is your plan with the library?

- A: To make SAE J1939 available for everybody

- Q: I don't have CAN-bus, but can I use this library anyway with UART, USB, WiFi etc?

- A: Yes. This is only a way to shape a message in a specific way.

- Q: Can I send data with this library, even if I don't have CAN-bus?

- A: Yes. There are something called DM14 transmit request, DM15 status response and DM16 binary transfer. Use that if you want to transfer data in an industrial way.

- Q: Can I send multi package messages from multiple ECU's to one ECU at the same time?

- A: No. If you starting to send multipackages from multiple ECU's to another ECU, then that ECU cannot understand the message. Transmit only multipackage messages one at the time if the destination address is the same.

- Q: I don't want to use

ANSI C (C89)with Open SAE J1939. Can I use the latest C standard with Open SAE J1939?- Yes, you can use the latest C standard with this library.

- Q: Is it possible to compile this library onto a Windows MS-DOS or Windows 95 machine?

- A C89 compatible compiler and an IDE and it should not be any problem

- Q: Can I adjust the memory occupied by the program?

- A: Yes, you can adjust the defines

MAX_PROPRIETARY_A,MAX_PROPRIETARY_BandMAX_PROPRIETARY_B_PGNSin the fileStructs.haccording to your use case. A 'sane' default value is provided, but you can set them to the minimum if proprietary PGNs support is not needed or increase it if more PGNs need to be used.Issues and answers

- A: Yes, you can adjust the defines

- I: I cannot compile this library. I'm using

Keil Microvision.- A:

Keil Microvisioncannot handle binary numbers such as0b010101. TrySTM32CubeIDEinstead becauseOpen SAE J1939is made inSTM32CubeIDE

- A:

- I: Can you provide us with some hardware examples for example

STM32?- A: Yes! There is a STM32 example how to get connection with CAN-bus including an interrupt listener for messages. Go to

Examples -> Hardwarefolder at look forCAN_STM32.txt. Also there is aUSBexample as well forQT C++.

- A: Yes! There is a STM32 example how to get connection with CAN-bus including an interrupt listener for messages. Go to